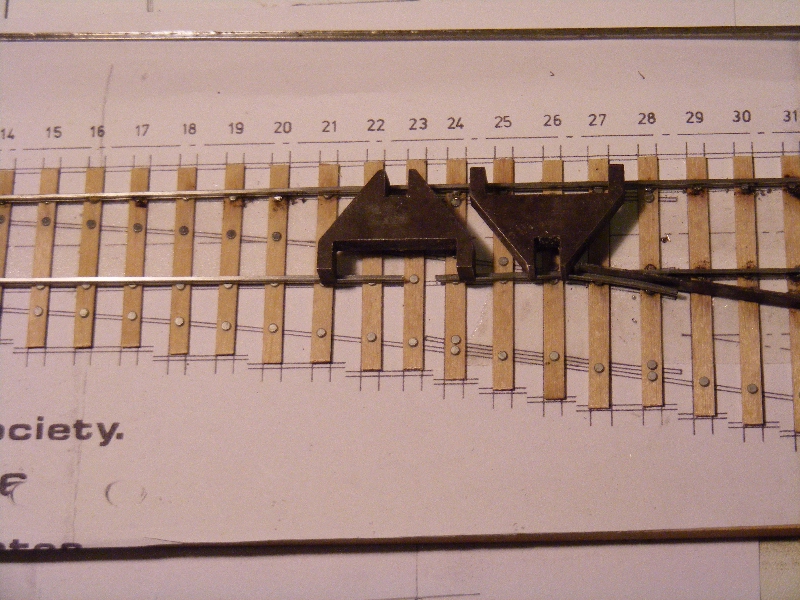

Going back to look at my first crossover for the layout in a bit more detail.

Xover 1.JPG

Compare with the real thing.

Brimsdown037.JPG

This photo was take on a cold frosty morning and really shows the timbers well.

Note how the timber ends on the left hand edge are more or less in line, whereas those to the right are most irregular. There is also some variation in the middle too. Something I have hopefully replicated on the model. There was another puzzle. When I first attempted to Templot this formation, I allowed increased track spacing because of the curvature, but this just did not work. There are only three timbers in the space between the ends of the wing rails of the two turnouts. This could only be achieved by reducing the track centres to standard spacing. Although this would not be allowed on a main line, I suspect that as this was only a one engine in steam area (typically a J15 or other small 0-6-0 for which the GER were so well known) and short wheelbase wagons were the majority of the traffic that there was sufficient clearance between the stock on each road. I have checked the result with a loco (in my case a BTH type 1, class 15) and wagon and it is not too bad, so don't assume the obvious is I suppose the moral here.

But why the odd timbering, which had me baffled for many years?

There is a clue in a 1938 map I recently discovered.

Brimsdown 1938.png

Note how the curving tracks at the bottom middle become single part way round the curve.

When I knew the area in the late 1960's the double track extended to somewhere near the right angle crossing at the top of the map and the engineering works had long gone. Indeed there was a new road running through the middle of where it once was.

I also have a 1947 LNER 40 foot to the inch map of the area and it was double track by then.

The conclusion is that due the the increased traffic demands of WW2, the single track was doubled with the new crossover installed from whatever materials were available. Incidentally from personal observation the crossover consisted of a left and right hand turnout rather than the usual arrangement.

Due to the severe curvature of the track at the bottom of the map, there was a sign prohibiting locos from proceeding much further than beyond the crossover to run round. It was about where the lane and foot path crosses the railway.

Regards

Tony.

You do not have the required permissions to view the files attached to this post.

Inspiration from the past. Dreams for the future.