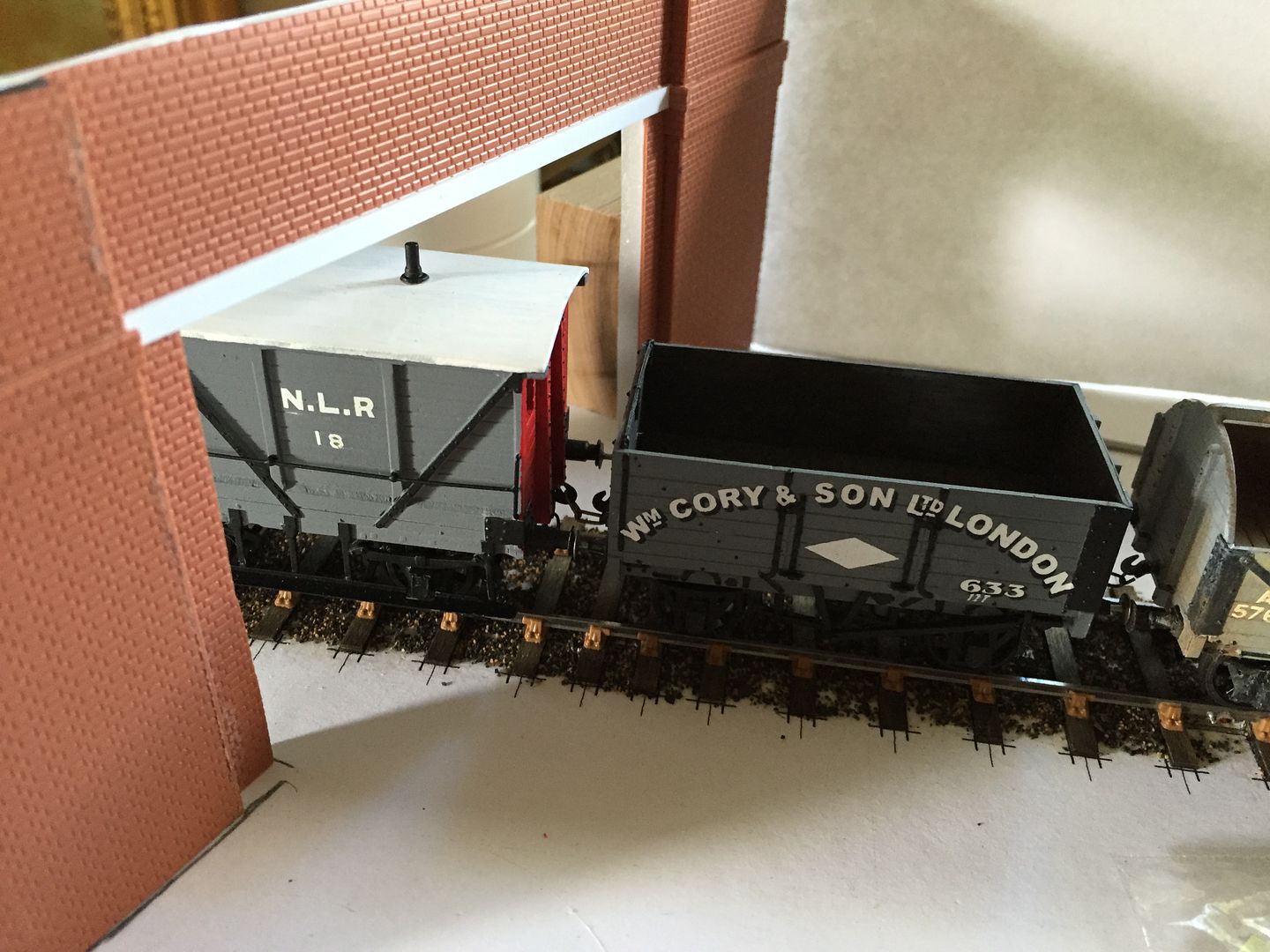

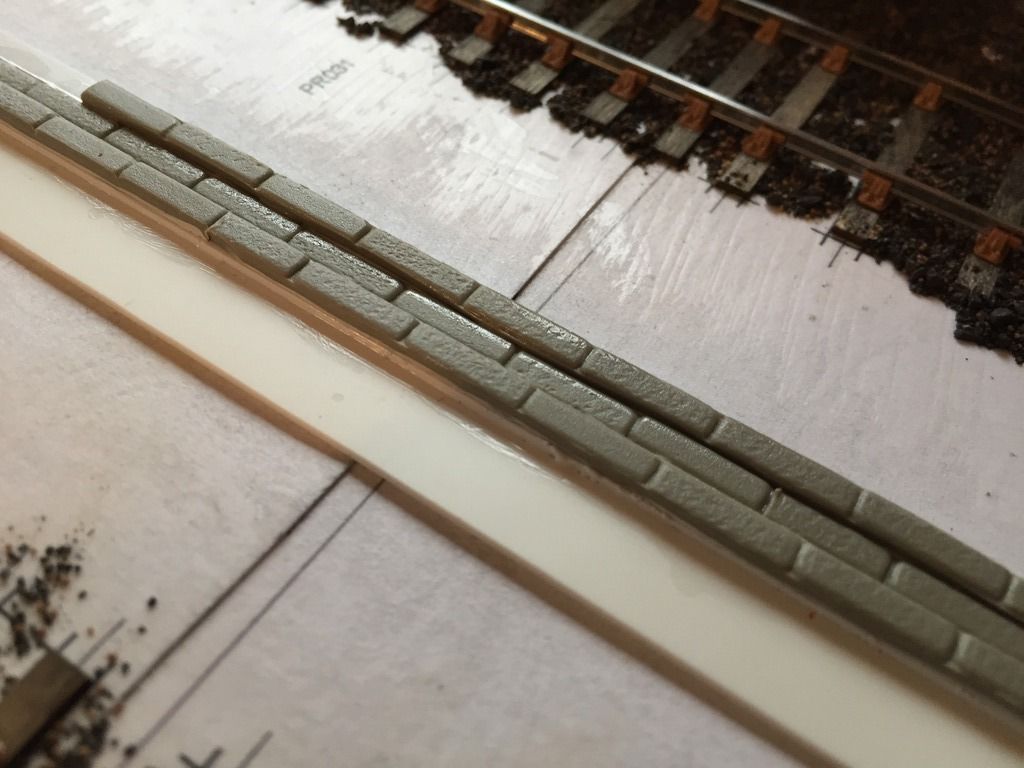

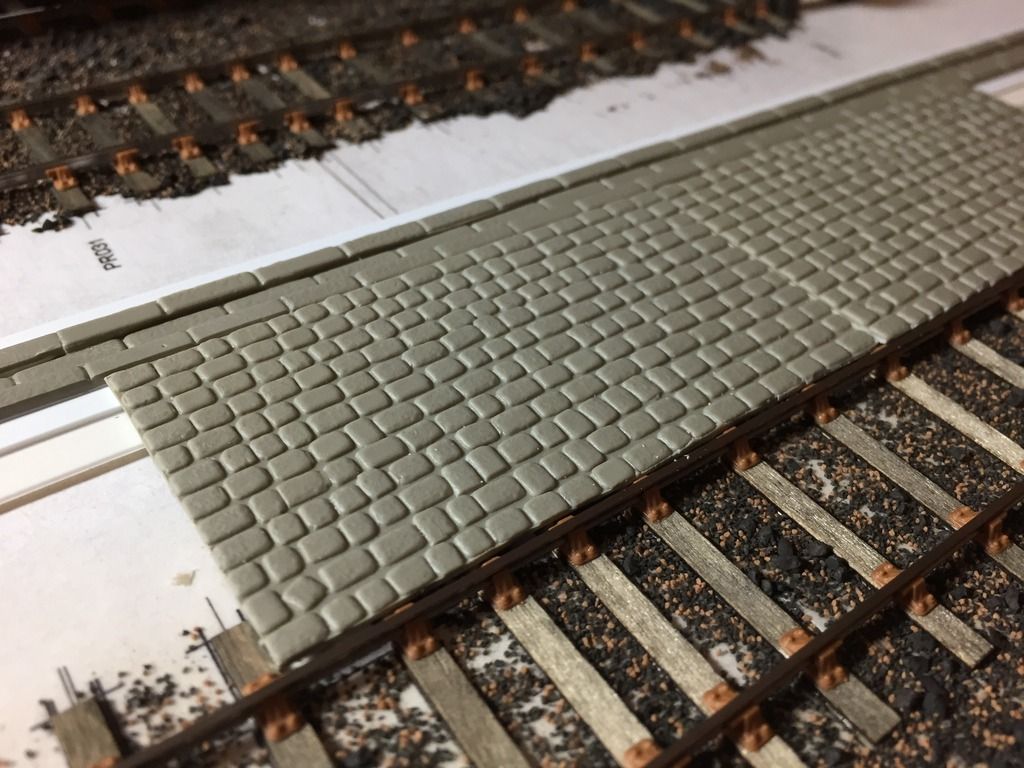

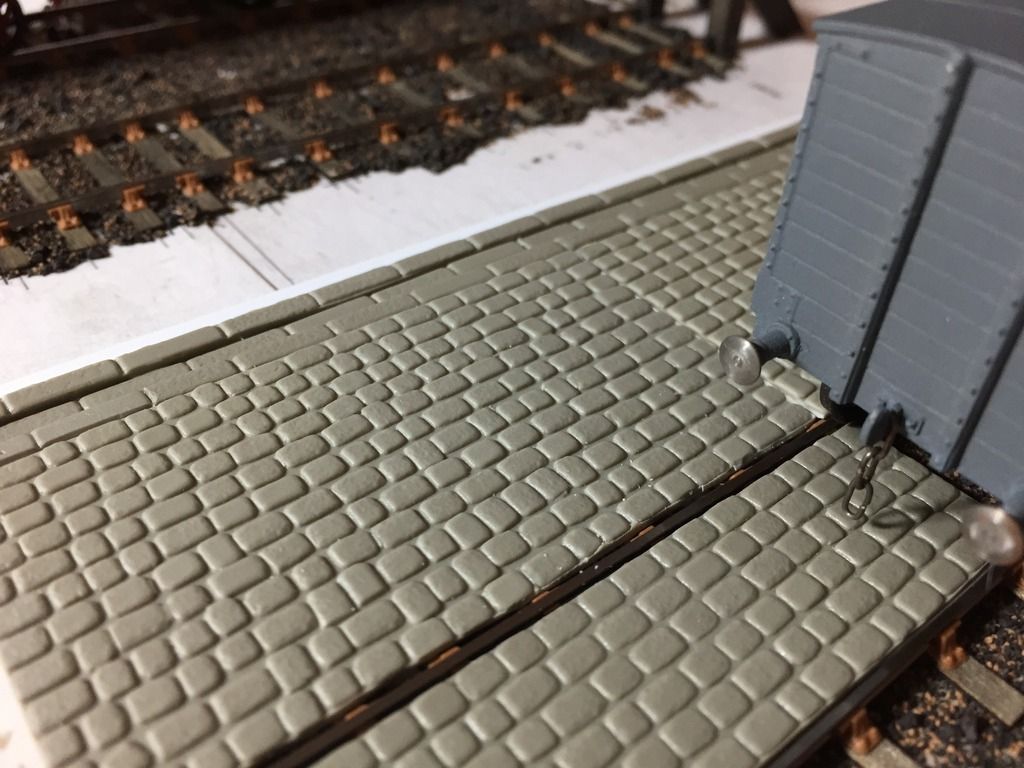

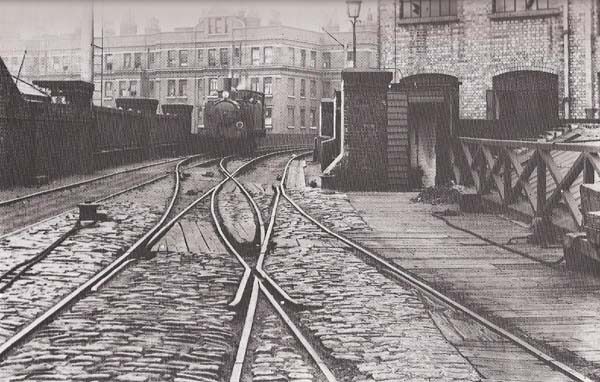

As I've been working on the setts I've been thinking about the front center of the layout. This area has always been a bit up in the air as to what would go there. It could be more setts, it could be dirt, or it could be something more substantial. I had originally tried to fit in an end loading dock, so that I could have an excuse to feature loaded machine trucks, but there wasn't sufficient room. It has occurred to me recently however that I could have a platform, or at least part of a platform, at the front of the layout. It would have a ramp down at the right hand end, and maybe a small crane at the left? With this on my mind I mocked it up from foam board and card. The curve isn't quite right and it's too close to the track, but it gives an idea.

The layout was originally conceived as having the four track mainline off scene but immediately in front of what is on scene. That's still what I have in mind, but if that is the case then this may not be the best place for the platform. I would appreciate input on the looks, realism, and practicality of putting the platform here. It would be quite some time before the layout is expanded, and it may never happen, so that may shape things as well.

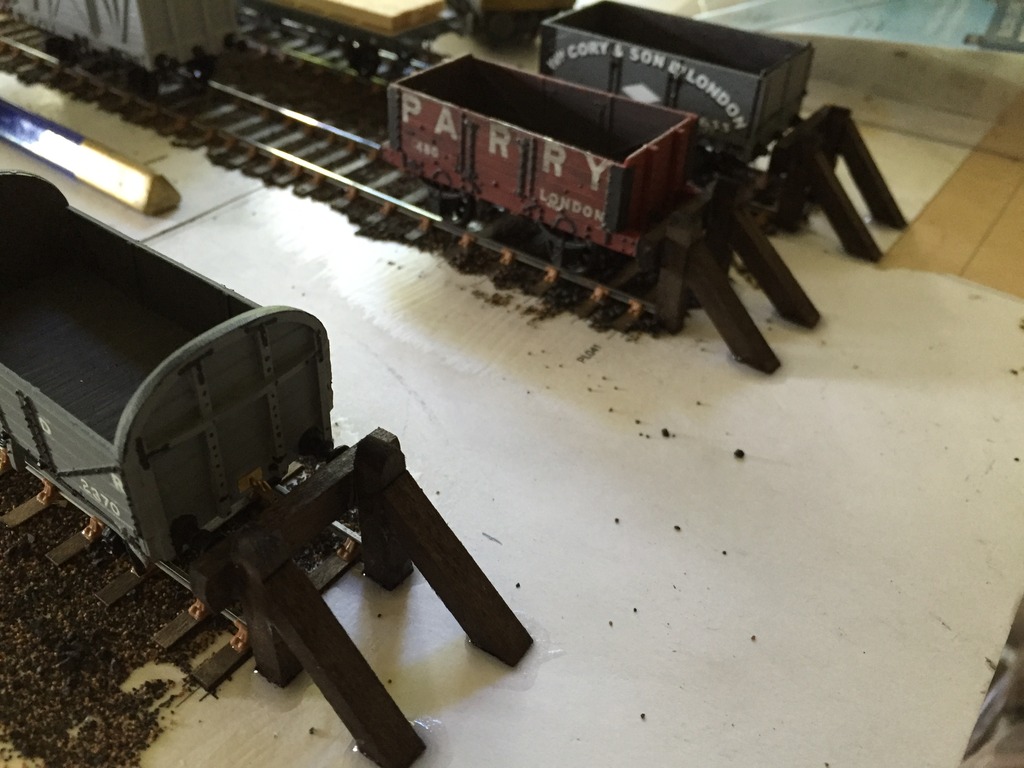

Here is the overall scene currently

With the platform in place

And from the other end

What do you think?