Ok fellow modellers.

I had an idea and implemented it. It is an idea that I have done similar before.

Now please note, if you have been following this thread you know the controversy and that I want to get things right.

To make things clearer here are the problems:

A) - Different Scale Drawings and text from different sources give different wheelbases and different sizes. These being...

- 3' bogey wheels or 3'6" ?

- Conflicting wheelbases for the Cambrian of

5’ 6” + 6’ 6½” + 8’ 3”

or 5' 9" + 6' 6" + 8'6"

and the Furness K2 being

5’ 9” + 6’ 8” + 8’ 6”

- Some sources and people are saying the two locomotives shared the exact same wheelbase, others not.

B) - These may be genuine variations that existed, or some information may clearly be wrong. Hard to know for sure. Awkward as there were a few builders and if there were variations this may be a reason.

C) - We (me included) tend to believe that the info we have is correct and everyone else is wrong. Your scale drawing or railway book is

king, bugger the rest! With confliction how do you know yours is right?

D) - Did the Furness K2 (21 Class) that came after the Cambrian 61 change any wheel sizes or wheelbase?

E) - If so repeat point A & B for the K2.

--------------

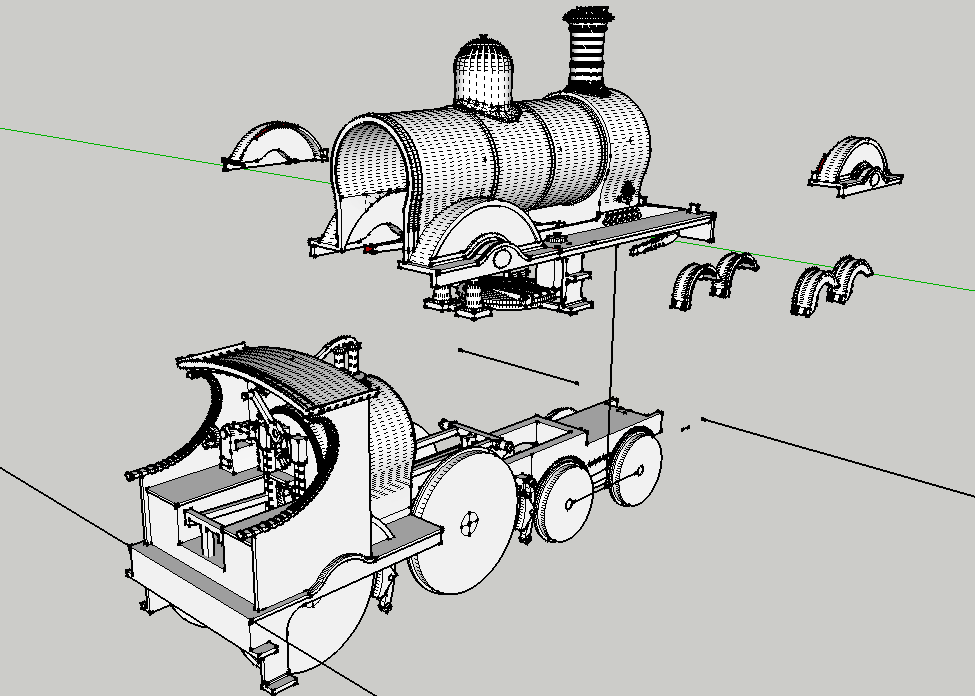

So, I'm still trying to get the bottom of this and I have done something interesting.

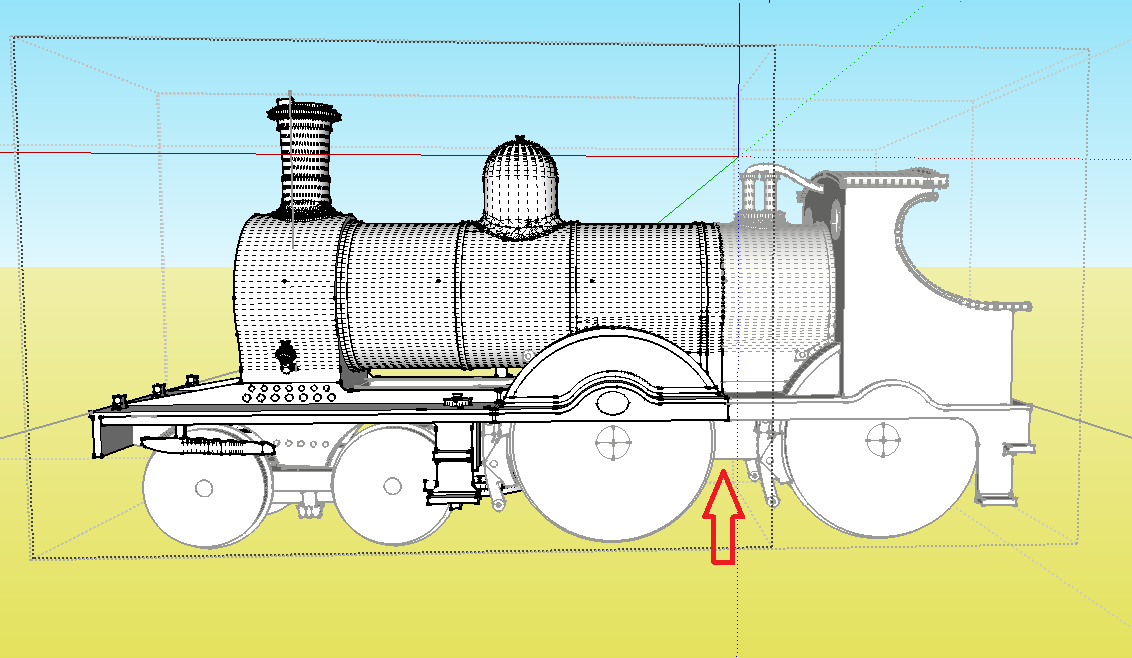

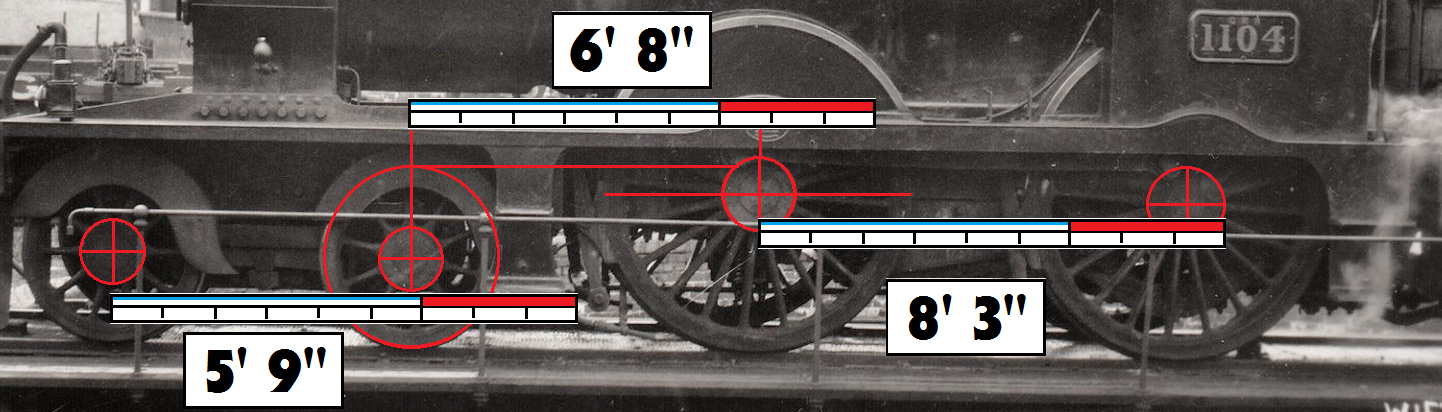

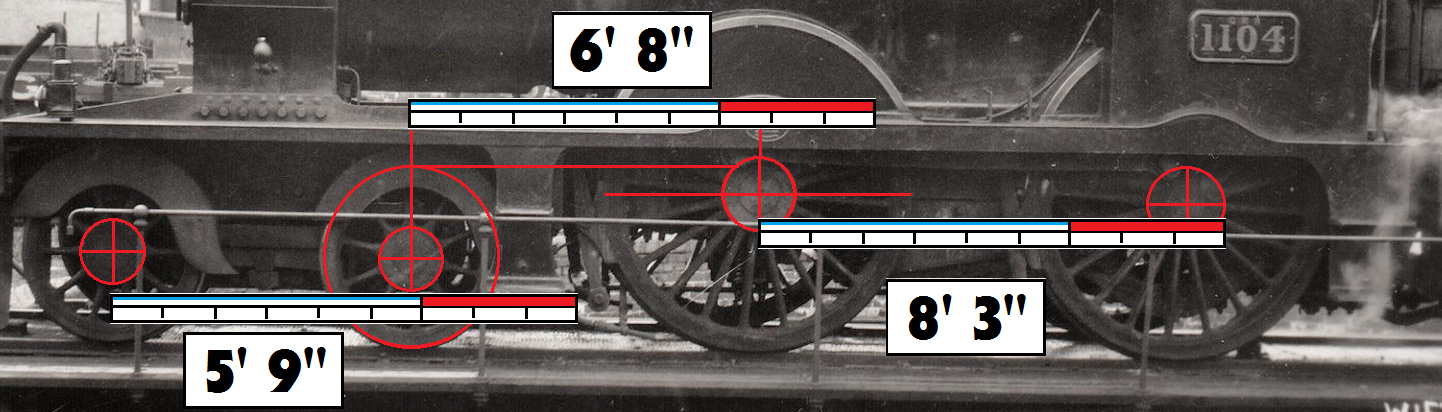

As a disclaimer I know that the prototype photograph of the Cambrian loco is not perfectly sideways, neither can it be due to the reality

of perspectives changing, neither can the following be considered 100% accurate, however, I've been as careful and exacting as I can going only by this photograph. Many thanks to Quarryscapes for providing it...

So with that I have to the best of my ability found the axle centre of the wheels and from the front driving wheel drew horizontal lines either side. This gives us the best approximation of 6 feet. Then a circle was drew around it as best as can be done with a less than perfect angle due to perspective shift.

The bogey wheels from the top centre have a line horizontal right towards the undisputed 6 foot driving wheel - as you can see this particular bogey is 3 foot 6 inches. No arguing there.

From the 6 foot horizontal line previously mentioned that red line was copied and pasted, converted blue and divided into 6 to represent individual feet. 3 extra feet were added based on copying and pasting effectually creating a Rule/Ruler. Again, I know the perspective shifts but this exercise is to try to establish what matches what data best based on this photograph.

By placing the rule at the key areas and referring to the 3 disputed wheelbases we can see what matches best and draw some conclusions.

According to this picture then, I estimate the wheelbase to be

5’ 9” + 6’ 8” + 8’ 3”

Which is different to ALL the 3 above! It matches one wheelbase only lest for the value of 8'6".

So, conclusion & Questions:

A) - If the above exercise is good enough to go by (seems clear to me) then we have a 4th wheelbase that may be the median truth. If it is wrong then

the wheelbase of 5’ 9” + 6’ 8” + 8’ 6” must be correct instead - I'm thinking this is likely. The far right perspective may skew the 3 inches out of scale.

B) - If this new wheelbase is correct then is it across the board for ALL the Class 61's or were there indeed variations?

C) - Did these dimensions transfer into the Furness K2 or is the K2 indeed different?

D) - If they did transfer and the K2 is the same, was the K2 fixed or did that have genuine variation?

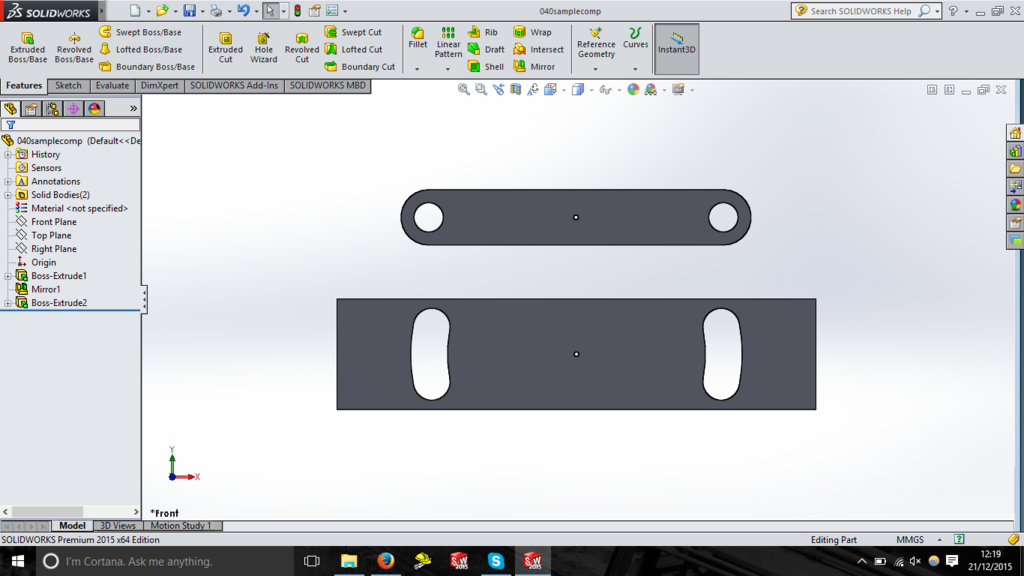

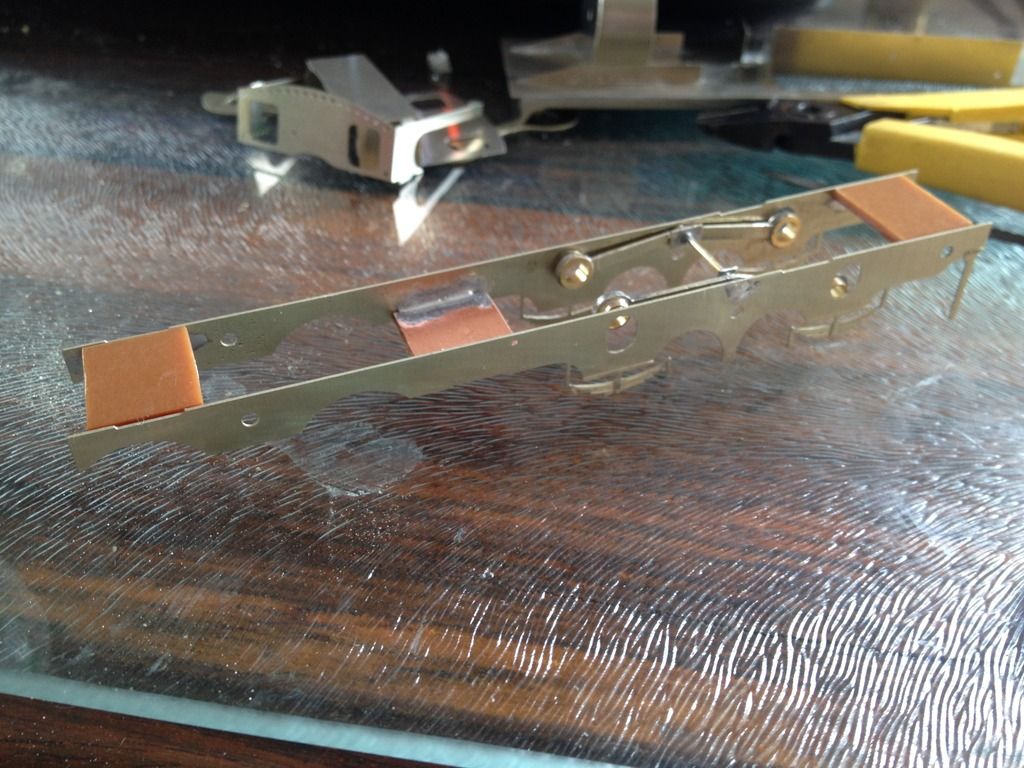

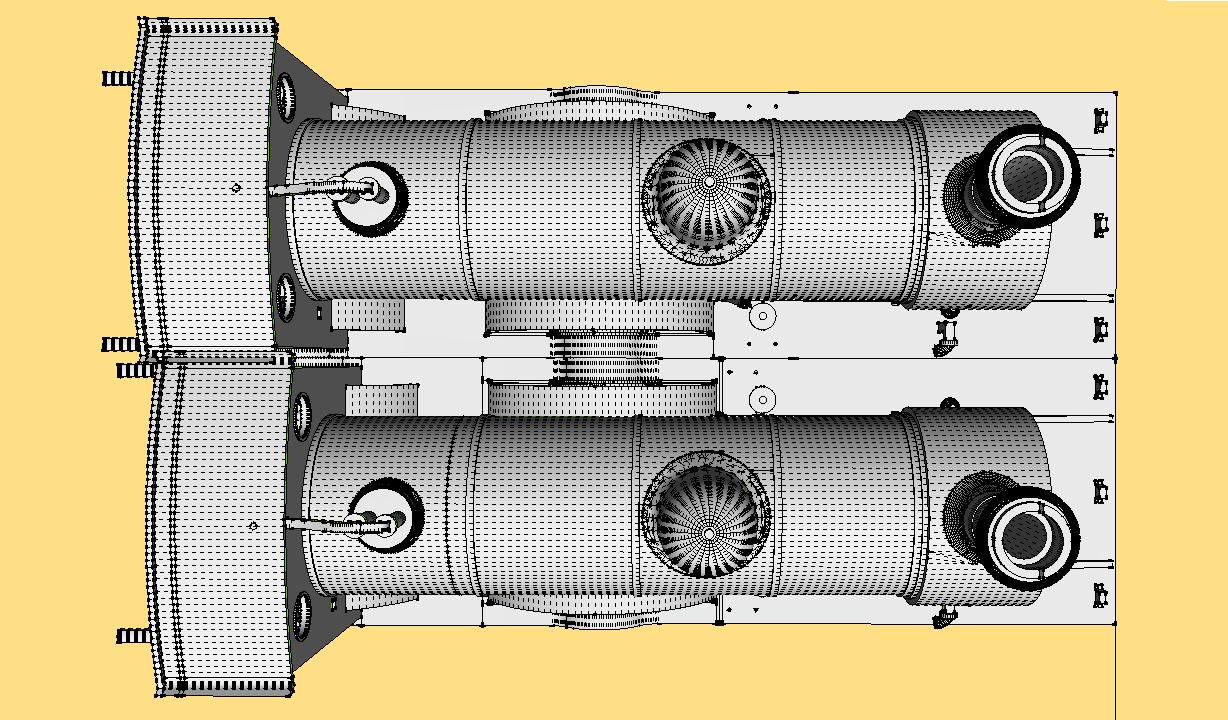

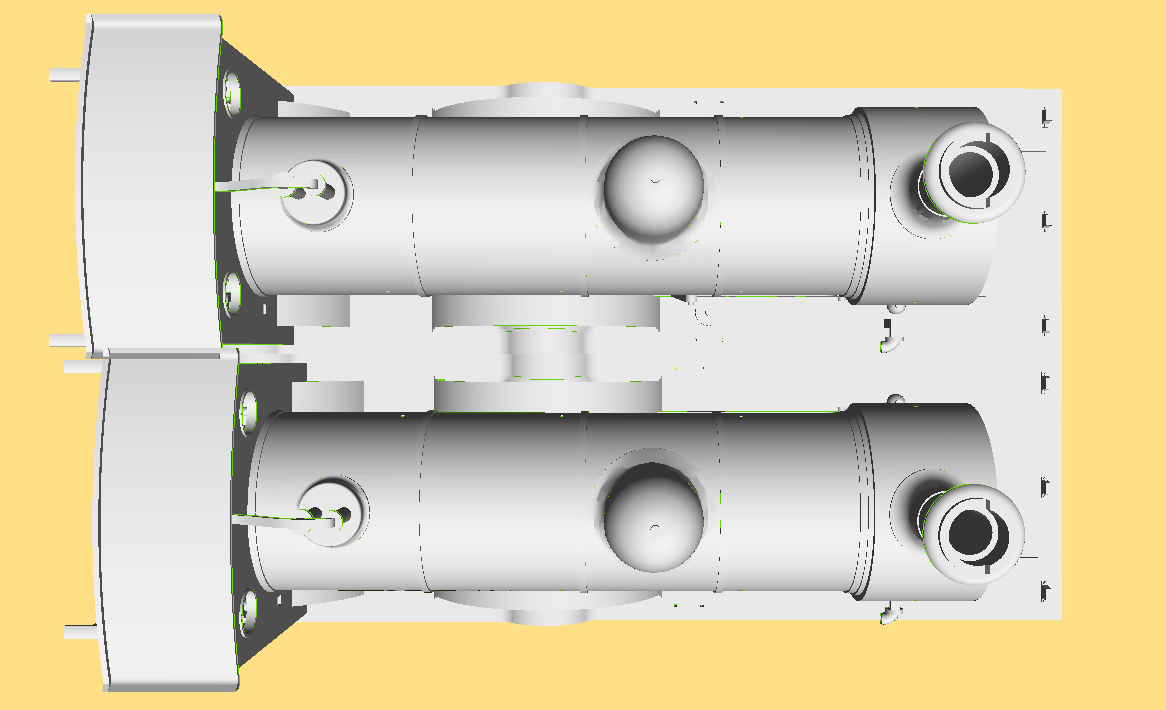

Model Considerations: The Furness K2 that is available has been built with a wheelbase of

5’ 9” + 6’ 8” + 8’ 6”

This exercise shows the wheelbase to be 5’ 9” + 6’ 8” + 8’ 3” or the same if the right hand value is perspective skewed too much.

The K2 model has been designed to use the 3' wheels not the 3' 6" but if you want bigger wheels this can easily be changed by filing a little extra clearance for the bogeys and when I upload them (if you want to) getting the bigger bogey splashers. The chassis meshes can always be altered to take the bigger wheels if necessary although if this post is true the then wheelbase can stay. BUT - does the K2 indeed have bigger bogey wheels? This is still to be answered.

For the Cambrian I'm likely to use the older model that is a wee longer based on this but again I'm straining to find the truth and I think I may have found some.

Thoughts please?

Additional Issue: For the tender I have different sources with different wheelbases too. So far it is a toss up between 6' 3", 6'6", and 6' perfectly. The model is 6' 3" but currently on hold due to these issues.

The model is designed with the 3'6" tender wheels, but other sources are saying 3'10" and another even larger than 3'6" so I'm drinking whisky.