Hi Ealing, I'm undecided on the buffers but the springs arn't in yet so it would be fairly quick soldering and swapping things about.

How do you know your chassis works with no wheels!!??

Maybe I got the wrong end of the brake pipe there.

Updatiostini:

Ok, where does this loco building n00b start....

Oh yes.

Firstly I'd like to appeal to those of you who know better and have built a siable bunch of these. Much of what I've written below will probably make you cringe and be a good example of how

not to do things! If that is the case then I'll just agree with you and try to learn. If your, like me fairly new to loco kit building then this post might provide some help or interest.

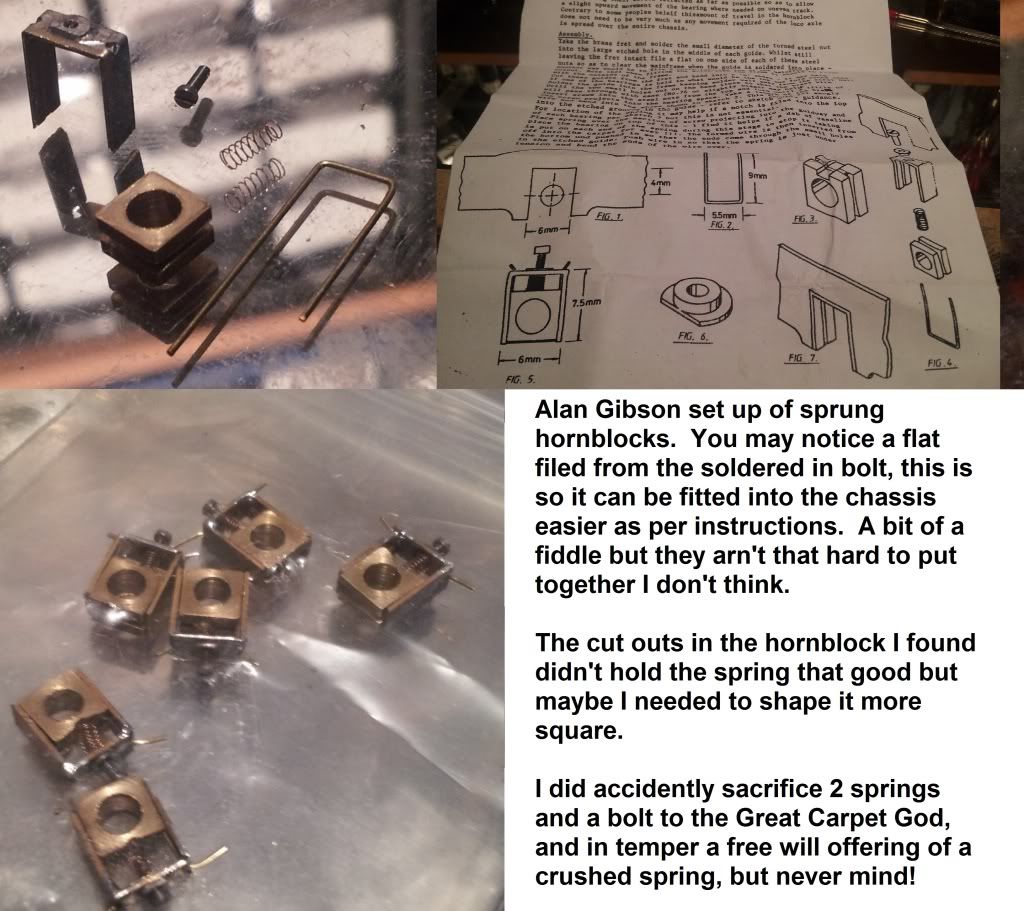

I had to have a real good think how to build this chassis becasue I had to literally ignore 90% of the instructions, instead relying on the component and arrow picture. Some of the text was useful but a lot of it wasn't because it only covered fixed axle guys and only had 00 or EM frame spacers. It might seem a sound assumption that only the exacting guys would want suspension and thus don't need instructions because they are so magic- but even they had to start with their first (me! Not my first loco build, but my first P4 locobuild and with springing). Anyway, after having a good look I got my Alan Gibson P4 frame spacers out and had another good look.

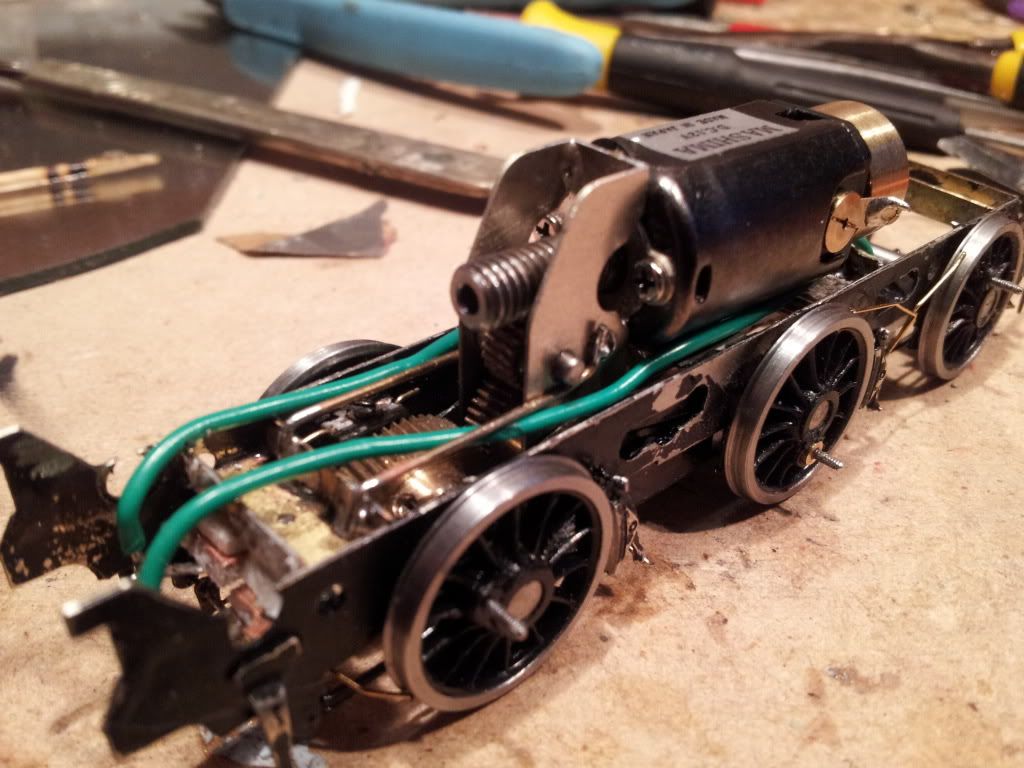

The Loco kit has the usual slot and tab method etched in for the frame spacers and a cylinder at each end that is secured to the frame sides via screw. Being 00 this was useless so I folded one of the '3 way' spaces to make a 'hollow rectangle' spacer. I hope I'm making sence but the pictures will reveal all.

Due to all this, and due to me using a Comet Models GB5 with 1/50 Drive Extender I couldn't put the P4 spacers in exactly the same place as the kit intended the others to go, so again I had to have a good think.

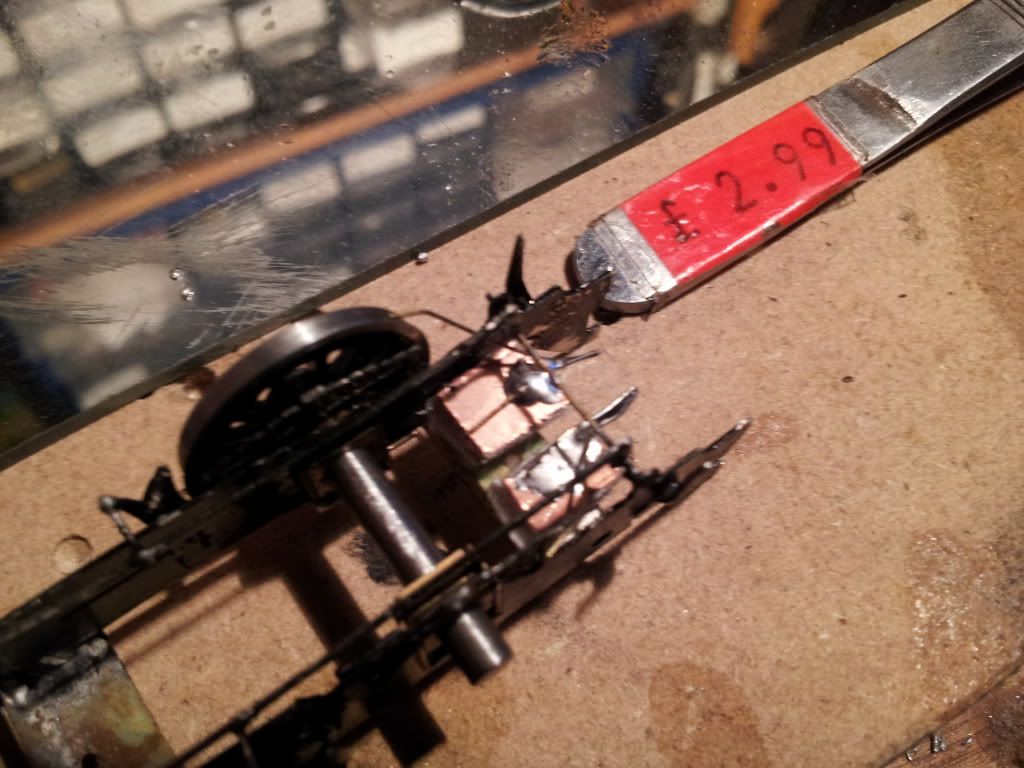

The following picture shows my highly sophisticated method of starting things coupled with a metal engineers square (pictured on top).

I haven't included any pictures between that an the finished article because it's a bit hard to convey what I did other than what I have wrote above, but suffice to say just keep checking on the plate glass that everything is square and only tack joint for a while becasue just when you think it's fine the metal cools down and it's out again!

Having graciosly recieved some axle/coupling rod jigs in the post from Mike G' I used them as intended by using the coupling rods as a jig, thankfully the kit was etched well and corrisponded with the hornblocks and everything almost lined up. There was about 1mm of difference because I had opened the hornblock holes out too much so getting this in the right place was a bit of a fiddle. The jig ends were too thick and not tapered but this wasn't really a problem because I just put a metal rule to the center of the jig pins and measureed the difference, and holding the coupling rods close. Again, hope that makes sence. I could grind them to a point I guess.

The coupling rods needed to be cut in half and laminated to provide a joint, this was easy but figuring out what to cut took more thinking than I originally envisaged. If I did it wrong I'd be in the sand trap. Fortunetly I did it ok.

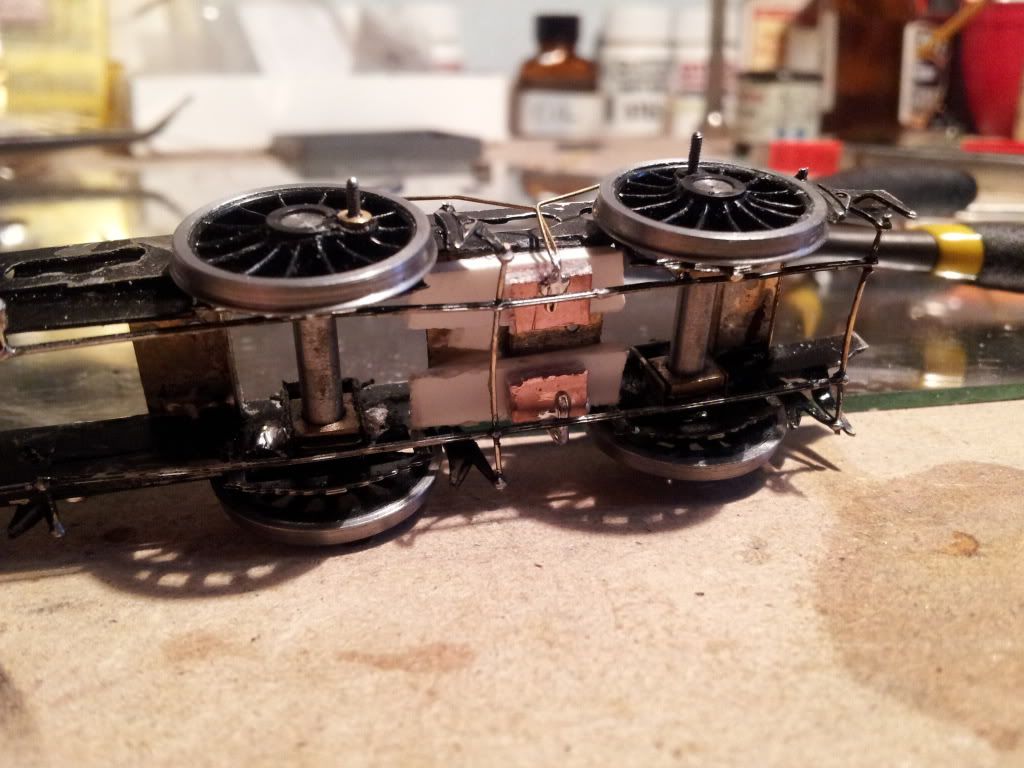

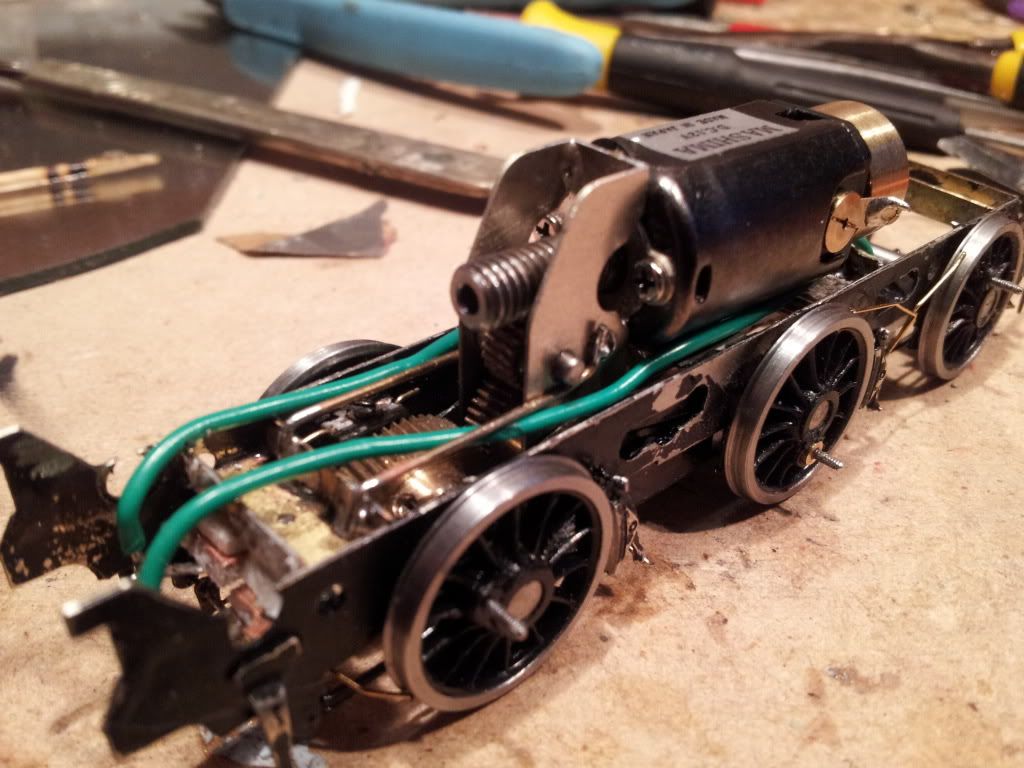

This is the chassis. Built bad and roughly in my opinion but that is due to experience lack.

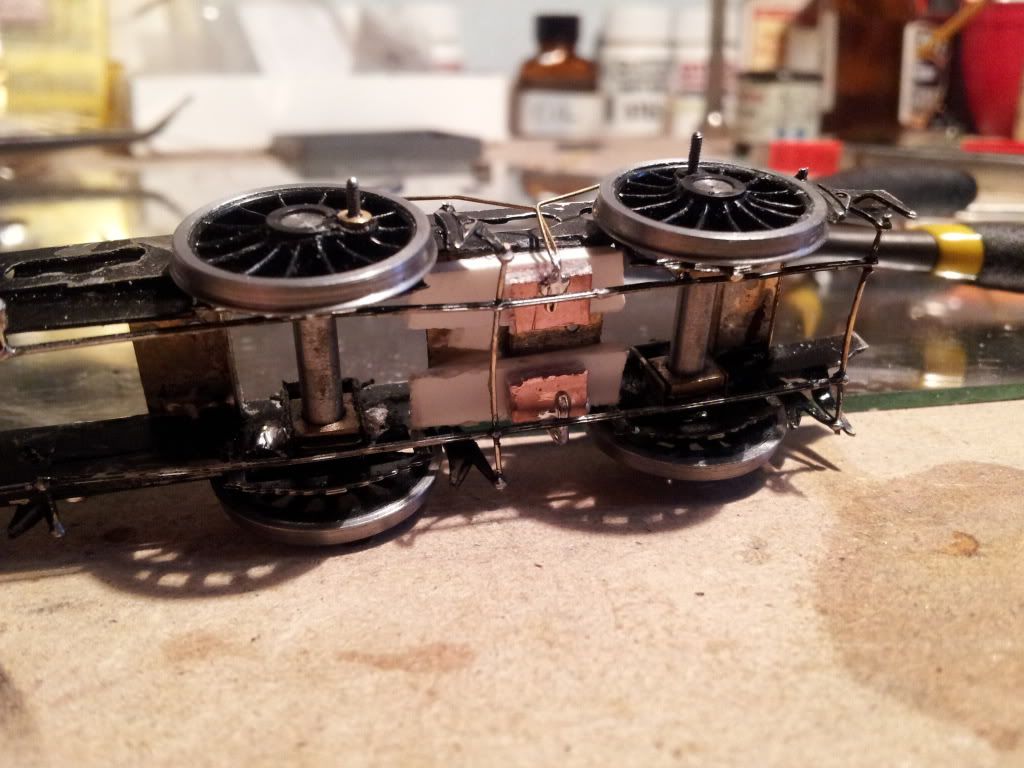

Pick ups are my own design after a long think and consultation of the forums and Ian Rice's book. I've seen some of the methods employed by others and they are much better being less obtrusive and probably better functioning. I'm just hoping that after painting them black and they model finished they won't look too out of place.

I'm probably shaming myself showing this but here goes. The horrid white plastic card is another attempt at reducing short circuits to provide another barrier and also some room for any liquids to run onto, like a collection trap - rather than seep underneith to the chassis. Details in the next paragraph.

I'd also like to say this is infact my 3rd attempt at doing the pick-ups. I used PCB and the first one was superglued but later came undone buggering everything, plus after a while it kept somehow shorting out. The second one I soldered and was fine initially but after a while also caused mysterious short circuits. I still can't fathom why this is the case becasue I checked repeatedly that nothing was touching and the only conclusion I can come up with is maybe some flux got in the way and tricked between both copper plates of the PCB andd fibreglass middle. I don't know. Suffice to say I then encounterd a really big mistake...

After washing the chassis and drying it, it seemed a little better but the tester needle was still moving half way, so I thought, 'How about using a hair dryer!? That's surely going to evaporate any moisture.' Right, but.

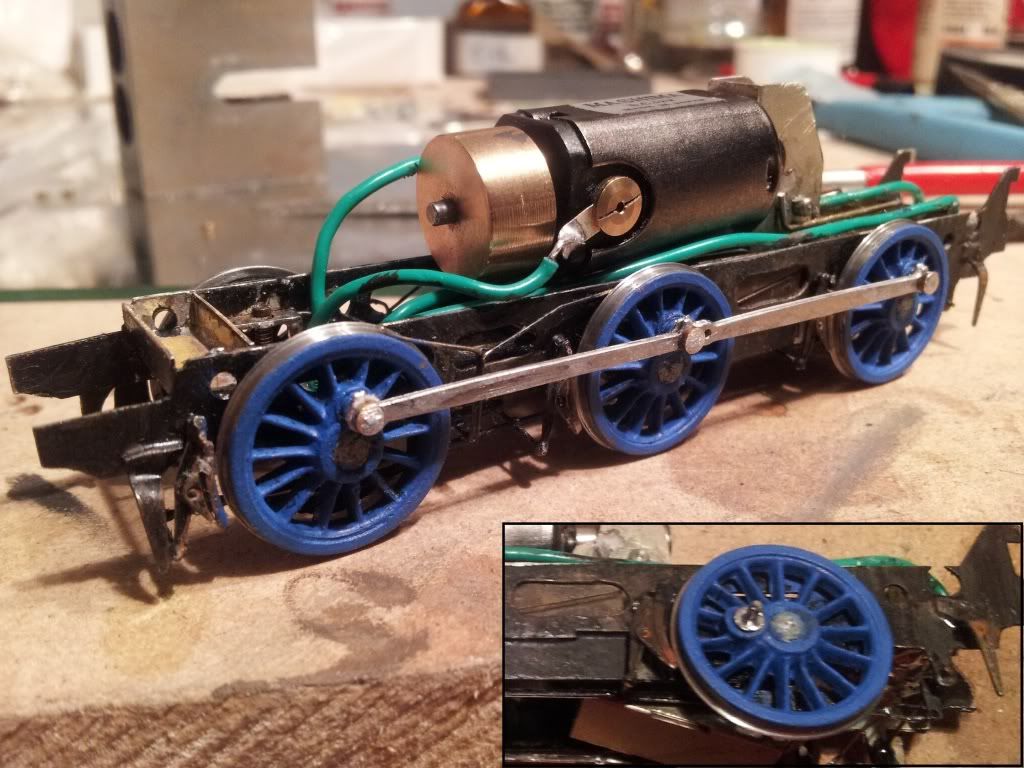

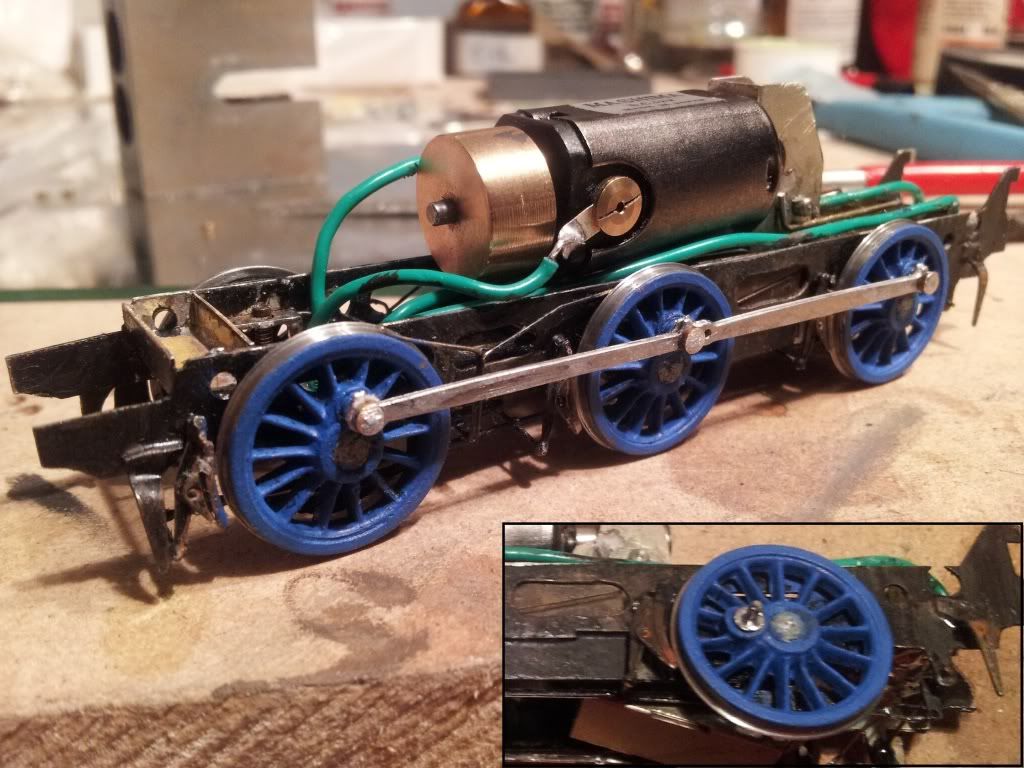

Alan Gibson wheels don't like hair dryers and two tyre rims fell off the plastic wheels proper!

*sigh* Powerbond 806 to the rescue again. I tried to get them on perfectly and I think I have but maybe at a major zoom I haven't, anyway, lesson learnt.

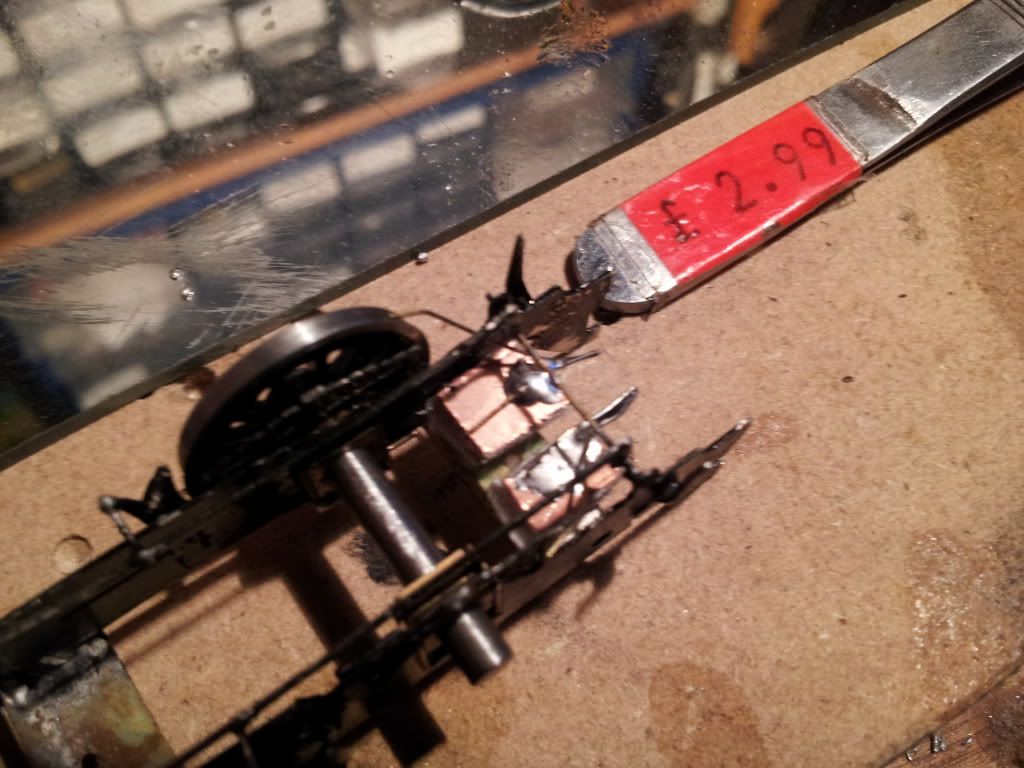

The next picture shows my method of fixing the gearbox to the frames to stop it doing a wiley jig everytime the engine changes direction. Two 0.7mm brass rods bent twice and soldered. Easy, simple, cheap, effective, adjustable, perfect in my opinion.

I had a lot of trouble getting good running and the gearbox in the above picture is my second. It still has the same problem as the first but not so bad, and after another of my infamous bodges it's even better. The cog directly below the motor worm has a hole in it for a grub screw. it doesn't matter weather you use the grub tightened to the layshaft, just sitting there dangelling its legs or removed; the worm struggles to negotiate the obstruction becasue it is IN THE TEETH! Silly design if you ask me. Fine at most speeds, even fairly slow, but for proper slow speeds it doesn't like it. My bodge was to insert some styrene rod into the hole via superglue, clip off the excess and then murder it with 350 degrees of soldering iron so that the remainded melts over the initial teeth. My own idea, that after a lot of detritus clean up, seems to have improved things somewhat. It still isn't perfect mind.

At some point in the build I also had to move a hornblock becasue it hadd about 1mm of horizontal play in it and after tis was sorted (by measuring in relation to other axles) it improved things no end.

Although I like Alan Gibson's hornblocks, once the axles are in they are only removable if you pull the wheel off, unlike other suspension methods I am interested in. I suppose building them slightly different to the instructions wouldn't be hard but I like the screw adjuster idea. Easy to change. After running the engine though it seems the suspension only works downwards. the weight of the loco' is designed to compress the springs 100% and so the hornblock is riding on the screw adjuster, ergo when the engine is running at a bumpy bit of decending track the springs push the wheel down into it - great, but when you come to a slight bump upwards the engine has to just bump itself up because the springs are already fully compressed. CSB I believe has the compression midway thus solving this but maybe a future build of mine will find out. Anyway, I prefer having hornblocks than non, is still better than a rigid chassis.

I painted the chassis at some point but not properly. I didn't use primer and I didn't spray becasue I didn't want to gum up the hornblocks or springs. Any ideas on the correct way? I just used brush on Humbrol enamel knowing that it sticks fairly well to bare metal and a chassis once assembled wouldn't be touched too much so I should get away with it. The same thing goes for wheels, I'm unsure on the best way.

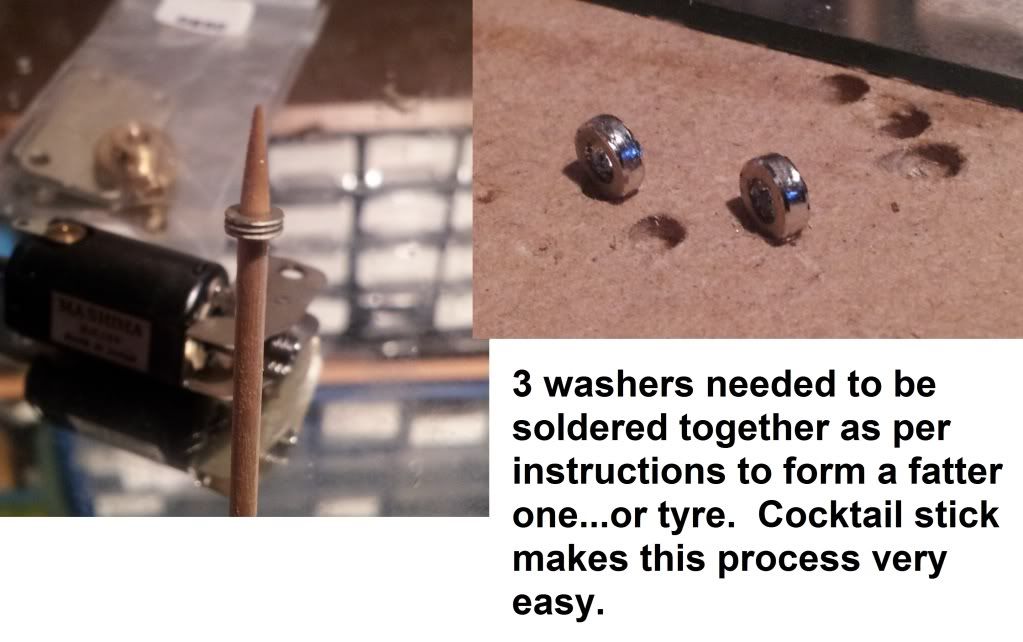

Whilst tweaking the running of the chassis I used bluetack as crank pin screws, supprisingly effective! Alan Gibson's crank pins needed a hole clearing in the coupling rods to 1.6mm's, but this was scaring me because as I reamed them I continued with one and it was getting so thin at the edges I honestly think papr was thicker. Scared of splitting it I crafted (lol) a circular lump from some scrap etch fret that ould fit in the hole, gummed it with solder and drilled a new hole. My method now was to gum up the crankpin threads with solder and just ride on them. Bad practice I know but with such thin rods I had little choice, maybe for an express locomotive there would be more metal to play with. After tweaking the running I just soldered a fat washer as a securing retainer using the paper washer method. Not sophisticated but then, I'm not sophisticated yet. As a loco building n00b I need to place function above other considerations. Because of my alternate method I wanted a washer as a smooth barrier between the wheel and the coupling rod, just like the intended bush would have done. I didn't have any thin enough so I melted them in. Rash, I know but it worked. You just need to be careful not to dwell too long and realign the crankpins slightly after they went drooped. The previous and following picture show the brass washers in a couple of places.

In hindsight I think in future I might use Markits/Romford crankpins intead. They are a little fatter but are smooth with no thread and I have a large supply of them already.

Oh yeah, I also had to re-drill brake hanger holes because I guess they were designed for those bigger older wheels, that or they were just being a milimeter or more cautious. I've set mine fairly close but careful that they don't touch either with or without compression.

Final picture. I repainted the chassis and added some good old gunk and rust and also the painted the wheels. I do need to touch things up in places and the blue is actually a different shade than what you see here but the unnatural light makes it look wrong.

What you think? Comments good or bad welcome, good critique only helps when implemented.