Will L wrote:You're not really disagreeing Ted, you're saying you don't believe that, in most circumstances, the lack of a link will not have any noticeable effect, a point of view which I did cover.

After a ponder on this in the shower this morning, (yes it works for me too Will!) in the case of the Fell, I am re-thinking the forces..

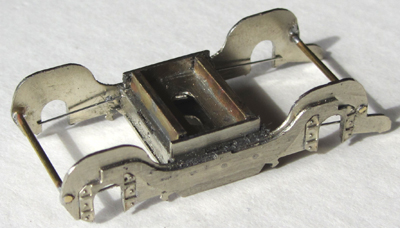

Considering the forces on the stretcher, remember that two axles, one at either end, are driven by a common gear train. So any reaction caused by a torque spike will apply to both ends of the stretcher.

Now, consider the reactions about one of the axle gears in isolation: When it's rotation is inhibited in some way, the stretcher will try to move the opposite way about the axle. Were the axle central in the stretcher, one side of it would want to move upwards, but the other side would want to move down.

Since the two gears on axles are in unison, (unless there is something very wrong!) then the one trying to push the stretcher up from one end will be opposed by the one at the other end pushing down, and the effect on each axle would just about double, one axle being unloaded and the other loaded by the same degree.

Another point - considering the magnitude of the force at the opposite end of the stretcher, ignoring the existence of the other gear, axle,and motor weight - is the length of the lever. The H/L final drive gear has a pcd of 8mm, so a radius of 4. Therefore, the torque force at the other end of the stretcher will be 4/26 or less than one sixth of that at the gear.

So with the weight of the motor on the stretcher, my opinion is that the torque reaction will neither lift an axle nor have any noticeable effect on traction. Should it cause a problem, the design of a reaction control linkage to prevent this will be interesting...

On most chassis you only find out what the lack of a the torque reaction link does when something else goes wrong. I once spent a lot of time trying to diagnose he running problems of a loco which persistently lifted one wheel off the track once per revolution. The presence of a torque reaction link would have made it much clearer where the real problem lay.

One wheel? Hmmm...

My introduction to the torque reaction effect was years ago with a DJH 7F; It is fitted with two pairs of springy beams and an RG4 driving the 3rd axle, the motor pointing backwards in the firebox. The first effect was a noticeable clonk on change of direction, but not enough to cause me to investigate.

Haulage with a heavy test train was great running forward, but under load in reverse the rear axle would lift clear of the rails by 1mm or more. What was happening was the motor was trying to rotate about the 3rd axle in the opposite direction and was pressing against the top of the firebox, the leverage pressing the 3rd axle down and lifting the 4th clear.

The solution was a horizontal hinged link on the gearbox, to a hinged fixed point on the chassis. Now the reaction forces in either direction have no effect on the axle loads.

Ted.