Driving wheel axle material

-

Jan

- Posts: 80

- Joined: Mon Aug 11, 2008 3:41 pm

Re: Driving wheel axle material

Hi Derek,

I'd like to give it a go.

Cheers

Jan

I'd like to give it a go.

Cheers

Jan

-

David Thorpe

Re: Driving wheel axle material

derekrussan wrote:The manufacturers have come back with a spec of +- 0.4mm on the 3.17mm and +- 0.03mm on the 2mm

I asume that you mean 0.04 on the 3.17 tube? That being the case, it's rather better than the +/- 0.13mm OD I was quoted on the tube I got. I'd certainly order some from you as it's something I've been looking for for ages.

DT

-

derekrussan

- Posts: 158

- Joined: Tue Jul 22, 2008 12:02 pm

Re: Driving wheel axle material

Previous posting corrected.

Order is now confirmed. Plenty of 1/8" (3.17mm) and a few bits of 2mm. I have created part numbers now so can be ordered.

Just to clarify,

O/D 3.17mm (+- 0.04mm). Specified as 0.5mm wall thickness, so I/D = 2.17 (+- 0.04mm). Stainless Steel Tube grade 316 supplied in 250mm lengths £4.00, Eileen's part no SST317217D

O/D 2.00mm (+-0.03mm). I/D 1.0mm (+-0.03mm). Stainless Steel Tube grade 304 supplied in 250mm lengths £4.00, Eileens part number SST2010D

Suitable cores are choice of, depending on clearance required:

1/8" - 3.17 = PWS160A (1.6mm dia Straight Piano Wire), SSRM15K (1.5mm Silver Steel), SSRM20K (2.0mm Silver Steel)

2mm = PWS081A (0.81mm dia Straight Piano Wire), PWS064A (0.64mm dia Straight Piano Wire)

Derek

Order is now confirmed. Plenty of 1/8" (3.17mm) and a few bits of 2mm. I have created part numbers now so can be ordered.

Just to clarify,

O/D 3.17mm (+- 0.04mm). Specified as 0.5mm wall thickness, so I/D = 2.17 (+- 0.04mm). Stainless Steel Tube grade 316 supplied in 250mm lengths £4.00, Eileen's part no SST317217D

O/D 2.00mm (+-0.03mm). I/D 1.0mm (+-0.03mm). Stainless Steel Tube grade 304 supplied in 250mm lengths £4.00, Eileens part number SST2010D

Suitable cores are choice of, depending on clearance required:

1/8" - 3.17 = PWS160A (1.6mm dia Straight Piano Wire), SSRM15K (1.5mm Silver Steel), SSRM20K (2.0mm Silver Steel)

2mm = PWS081A (0.81mm dia Straight Piano Wire), PWS064A (0.64mm dia Straight Piano Wire)

Derek

Derek Russan, Eileens Emporium.

-

derekrussan

- Posts: 158

- Joined: Tue Jul 22, 2008 12:02 pm

Re: Driving wheel axle material

Both now in stock.

Only one order received so far

Only one order received so far

Derek Russan, Eileens Emporium.

-

Jan

- Posts: 80

- Joined: Mon Aug 11, 2008 3:41 pm

Re: Driving wheel axle material

derekrussan wrote:Both now in stock.

Only one order received so far

Deux, Derek

-

Paul Townsend

- Posts: 964

- Joined: Mon Sep 14, 2009 6:09 pm

Re: Driving wheel axle material

derekrussan wrote:Both now in stock.

Only one order received so far

Just you wait until Leatherhead when we can all save on postage.

Bet you run out there!

-

derekrussan

- Posts: 158

- Joined: Tue Jul 22, 2008 12:02 pm

Re: Driving wheel axle material

Thanks for the reminder to take them  . I have been so busy recently it did not even cross my mind. I have lots of 1/8" but only got a few 2mm to try (currently 6 left), so if you need 2mm it will be better to pre-order. I will get more in after Scaleforum.

. I have been so busy recently it did not even cross my mind. I have lots of 1/8" but only got a few 2mm to try (currently 6 left), so if you need 2mm it will be better to pre-order. I will get more in after Scaleforum.

Derek

Derek

Derek Russan, Eileens Emporium.

-

Paul Willis

- Forum Team

- Posts: 3048

- Joined: Sun Jul 20, 2008 6:00 pm

Re: Driving wheel axle material

derekrussan wrote:Both now in stock.

Only one order received so far

You will have realised that as it will now be a stock item, the urgency to be part of a one-off order will have been removed...

I'm sure that you'll find it will be a product line that is a steady mover, but not in the large initial quantity that you might have expected. We don't all build models that quickly!

And thanks for taking the initiative anyway - I'm sure that I'll be having some off you in the near future

Cheers

Flymo

Beware of Trains - occasional modelling in progress!

www.5522models.co.uk

www.5522models.co.uk

-

derekrussan

- Posts: 158

- Joined: Tue Jul 22, 2008 12:02 pm

Re: Driving wheel axle material

I was expecting it to be a steady mover for all the reasons you give, however that applies more to repeat orders than first orders. I am also sure the uptake will increase when the feedback from those I have shipped to hits the forum.

Derek

Derek

Derek Russan, Eileens Emporium.

-

Jan

- Posts: 80

- Joined: Mon Aug 11, 2008 3:41 pm

Re: Driving wheel axle material

derekrussan wrote:I was expecting it to be a steady mover for all the reasons you give, however that applies more to repeat orders than first orders. I am also sure the uptake will increase when the feedback from those I have shipped to hits the forum.

Derek

Mine was waiting fro me when I arrived back in the Office after a Conference last week followed by a few days away.... Looks very good. Appears dimensionally accurate to my non-bionic eye (i'll take the micrometer into the office tomorrow....). Usual excellent packing from Eileen's.. Now to find the trans-dimensional Key of Time's Understanding and thereby gain access to the Realm of Relaxation, fortified with a healthy draught from the Attendant Pool of Knowledge that is this Forum...

-

Paul Willis

- Forum Team

- Posts: 3048

- Joined: Sun Jul 20, 2008 6:00 pm

Re: Driving wheel axle material

Jan wrote: Usual excellent packing from Eileen's.. Now to find the trans-dimensional Key of Time's Understanding and thereby gain access to the Realm of Relaxation, fortified with a healthy draught from the Attendant Pool of Knowledge that is this Forum...

You are in a square room with stone walls. There are exits North, East and West.

On the floor lies an axe, a small pool of blood and a number of wood shavings. Standing by the axe is a bearded shopkeeper...

Flymo

Beware of Trains - occasional modelling in progress!

www.5522models.co.uk

www.5522models.co.uk

-

LesGros

- Posts: 546

- Joined: Thu Oct 08, 2009 10:05 pm

Re: Driving wheel axle material

Flymo wrote:

It wisnae me!

Besides, I retired from Maplin Electronics ages ago...

.

On the floor lies an axe, a small pool of blood and a number of wood shavings. Standing by the axe is a bearded shopkeeper...

It wisnae me!

Besides, I retired from Maplin Electronics ages ago...

.

LesG

The man who never made a mistake

never made anything useful

The man who never made a mistake

never made anything useful

-

derekrussan

- Posts: 158

- Joined: Tue Jul 22, 2008 12:02 pm

Re: Driving wheel axle material

I have sold a fair few now, any feedback on how well they wotk?

Derek

Derek

Derek Russan, Eileens Emporium.

-

Alan Turner

- Posts: 643

- Joined: Sun Jul 20, 2008 4:24 pm

Re: Driving wheel axle material

I bought a couple of lengths at S4um. If have tried some AG "00" wheels that I keep for experimenting with. It was a good firm fit and they looked that they would do a good job.

Alan

Alan

-

David Thorpe

Re: Driving wheel axle material

I haven't actually used them yet - they're scheduled for use on my next loco build which should start within the next week or three. Like Alan, however, I've tried both the 1/8" and 2mm for fit on the respective Gibson wheels and they seem perfect, so I'm anticipating that they'll do an excellent job.

DT

DT

-

derekrussan

- Posts: 158

- Joined: Tue Jul 22, 2008 12:02 pm

Re: Driving wheel axle material

Thanks for the feedback, I will now order more as I have run out of the 2mm.

Derek

Derek

Derek Russan, Eileens Emporium.

-

hollybeau

- Posts: 91

- Joined: Thu Jul 30, 2009 10:03 am

Re: Driving wheel axle material

I realise that this thread has not been added to in nearly a year but I thought I would reawaken it if I may to ask if anyone has actually used these materials to make split axles?

I bought the tube and associated rod from Eileen's some months ago (together with its 2mm equivalents) as a trial and have just today got round to making a start. My initial opinion is favourable but with a few reservations. The first of these concerns the apparent lack of strength which is perhaps surprising given that the tube material is stainless steel. Perhaps because it has been drawn into a tube as opposed to being machined from the solid gives it this property. However, my 250mm long trial length had a perceptible curve in it . (Despite being well packaged by E.E). Now that it has been cut into axle lengths the problem, if there ever was one, is not apparent and rolling these cut lengths of tube along some plate glass shows no irregular "wobbles". Perhaps I am worrying unnecessary but has anyone else noted this and, more importantly, does it matter?

The steel inner rod comes coated in some sticky grease (quite sensibly to prevent it rusting) and I have removed that with some thinners. It is a nice snug fit inside the tube which is of course good, in terms of providing strength , but bad if, when fitted, it shorts out the two sides of the tube. I have attempted to counter this by lightly reaming the tube from both ends and rubbing down the rod with 1200 grade wet and dry, used dry. I have then upended the rods and dribbled some thin cheap super glue down the rod. When dry (a few minutes) I rubbed it down again lightly with the wet and dry. I have tested this with a meter and this has given the rod a thin insulating layer. Finally, using a smear of Araldite (the proper 24 hour stuff and not that which goes off in 5 mins) I have carefully slid the rod in place. The Araldite, in its freshly mixed state, seems to act like a grease and let the rod be pushed in fairly easily. The axles are curing on the radiator as I write.

If they prove to be succesful (or indeed otherwise) I will write again. In the meantime it would be interesting to know of other people's experiences. I hope the silence does not mean that others have not been succesful!

Incidentally, the axles are to go with some Gibson brass-centred driving wheels which I have previously written about on this forum. They are also to be the subject of an article or two in forthcoming editions of Scalefour News.

Bryan

I bought the tube and associated rod from Eileen's some months ago (together with its 2mm equivalents) as a trial and have just today got round to making a start. My initial opinion is favourable but with a few reservations. The first of these concerns the apparent lack of strength which is perhaps surprising given that the tube material is stainless steel. Perhaps because it has been drawn into a tube as opposed to being machined from the solid gives it this property. However, my 250mm long trial length had a perceptible curve in it . (Despite being well packaged by E.E). Now that it has been cut into axle lengths the problem, if there ever was one, is not apparent and rolling these cut lengths of tube along some plate glass shows no irregular "wobbles". Perhaps I am worrying unnecessary but has anyone else noted this and, more importantly, does it matter?

The steel inner rod comes coated in some sticky grease (quite sensibly to prevent it rusting) and I have removed that with some thinners. It is a nice snug fit inside the tube which is of course good, in terms of providing strength , but bad if, when fitted, it shorts out the two sides of the tube. I have attempted to counter this by lightly reaming the tube from both ends and rubbing down the rod with 1200 grade wet and dry, used dry. I have then upended the rods and dribbled some thin cheap super glue down the rod. When dry (a few minutes) I rubbed it down again lightly with the wet and dry. I have tested this with a meter and this has given the rod a thin insulating layer. Finally, using a smear of Araldite (the proper 24 hour stuff and not that which goes off in 5 mins) I have carefully slid the rod in place. The Araldite, in its freshly mixed state, seems to act like a grease and let the rod be pushed in fairly easily. The axles are curing on the radiator as I write.

If they prove to be succesful (or indeed otherwise) I will write again. In the meantime it would be interesting to know of other people's experiences. I hope the silence does not mean that others have not been succesful!

Incidentally, the axles are to go with some Gibson brass-centred driving wheels which I have previously written about on this forum. They are also to be the subject of an article or two in forthcoming editions of Scalefour News.

Bryan

-

Paul Townsend

- Posts: 964

- Joined: Mon Sep 14, 2009 6:09 pm

Re: Driving wheel axle material

hollybeau wrote:I realise that this thread has not been added to in nearly a year but I thought I would reawaken it if I may to ask if anyone has actually used these materials to make split axles?

I bought the tube and associated rod from Eileen's some months ago (together with its 2mm equivalents) as a trial and have just today got round to making a start. My initial opinion is favourable but with a few reservations.

If they prove to be succesful (or indeed otherwise) I will write again. In the meantime it would be interesting to know of other people's experiences. I hope the silence does not mean that others have not been succesful!

Incidentally, the axles are to go with some Gibson brass-centred driving wheels which I have previously written about on this forum. They are also to be the subject of an article or two in forthcoming editions of Scalefour News.

Bryan

I used this method successfully last winter, with SS tube obtained from an Ebay supplier before Derek jumped in.

I used a directly obtained supply and Eileen's with similar success for last winter's NG 4' 8.5" loco.

Current loco on the bench can't really be converted to Splits.

Next loco to be started, currently planning chassis, will be the first ever ( ??) 7ft Broad Gauge, Split axle, DCC job, with CSBs too if I can.

That is why I needed long SS tubes as the EMGS/ Branchlines ones are too short.

Biggest difficulty I see is combining CSBs with Split frames....extra insulation issues arise 8-{

Anyone got experience of that combination for any gauge?

-

Russ Elliott

- Posts: 930

- Joined: Thu Jun 02, 2011 6:38 pm

Re: Driving wheel axle material

paultownsend wrote:Anyone got experience of that combination for any gauge?

I think you know the answer to that Paul, so we're all applauding you as volunteer trailblazer. Imagine the cross-pieces below split with copperclad bridges, and it could be some sort of way forward:

-

John Palmer

- Posts: 825

- Joined: Fri Jul 15, 2011 11:09 pm

Re: Driving wheel axle material

paultownsend wrote:Biggest difficulty I see is combining CSBs with Split frames....extra insulation issues arise 8-{

Anyone got experience of that combination for any gauge?

Paul, I don’t understand where these insulation issues arise. Each CSB will be attached to one frame on each side, and as such will form part of the electrical ‘unit’ that needs to be insulated from the corresponding frame/beam on the opposite side. The need for insulating frame stretchers appears to be exactly the same as in any split axle/split frame set-up. Is there something obvious that I have missed?

It’s quite true that in a CSB implementation you will need to keep the beams clear of frame stretchers, either by judicious positioning of the stretchers themselves or by forming appropriate cutouts in them through which the beams pass. But this is more straightforward than any arrangement involving a central equalising beam, for example, the pivot for which will probably have to take the form an additional split axle.

So far as I can see, a combination of CSB’s and split frames/axles ought to be plain sailing. What’s more, if your chosen prototype is a double framed engine, you won’t even have the problem of manufacturing split axles with blind bores in order to get good looking axle ends – you can just let the Araldite ooze out of the end of your SS tube.

My preferred stretcher material would be PCB with copper facing on both sides, so that both can receive solder fillets to unite the stretcher with the frame on each side.

-

hollybeau

- Posts: 91

- Joined: Thu Jul 30, 2009 10:03 am

Re: Driving wheel axle material

I am pleased to hear that you managed to get these materials to work together, Paul. Can I ask, when using the tube and rod from Eileen's, how you cut the tube after assembling it onto the rod? I ask because my own experiments have been complete failures. I attempted to cut the first one on the lathe using a sharp thin parting tool but whether I got the height wrong or the cutter was just not sharp enough it deformed the last vestiges of the stainless steel tube, pressing it through the superglue coating and shorting it out. I had a similar problem when cutting the axles to length. There was no obvious way back from there and that axle had to be binned. My second attempt used a Dremel and carborundum cutting disc but with the same result. My third and final attempt was with a piercing saw and a new, and very fine blade but that too resulted in shorting out (I had checked before cutting and the tube and rod were insulated from each other).

I have since had more success with some other stainless tube - same outside dimension but thinner walled and when this is used with the rod suplied by Eileen's provides more clearance and therefore less chance of material breaking through and shorting.

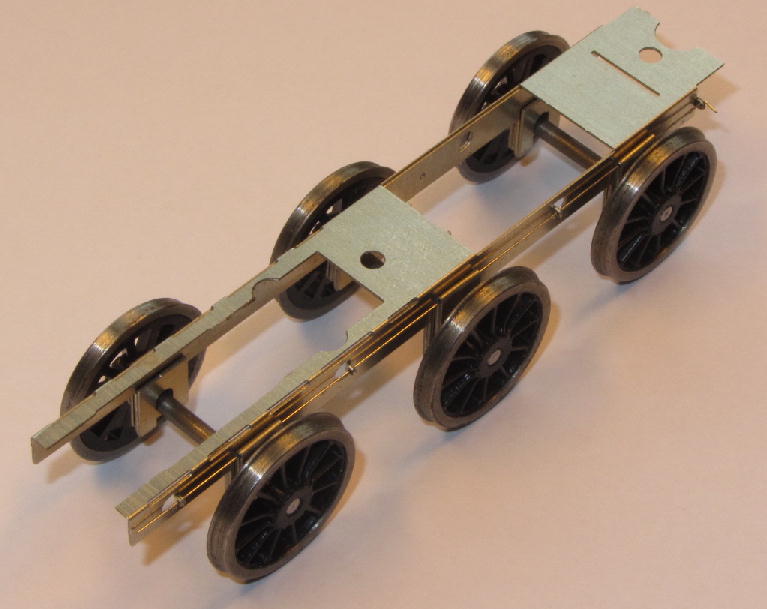

Today I have managed to assemble these and have them installed on a chassis for a Midland 1F (modified Craftsman) as shown below (please forgive the poor focusing on the photograph: I was anxious to get something posted quickly in response to the above). What (hopefully) the photo shows is the use of split axles and frames with CSB's (and the Gibson brass-centred wheels). I have built about six locos over the last two years to this spec (but this is the first with brass wheels) and oddly enough had not even given a thought to the alleged complexities of mixing CSB's with split frames. I'll try and get some better photos in due course. The red colouring on the wheels by the way is the remnants of some jewellers rouge I have been using to polish the treads. It works a treat but is a sod to clean off.

Here's the photo:

You may be able to see that I have filed the axle on the driven axle down to the boss and the smaller rod can just be seen surrounded by the light grey that is araldite/tube. The other axles have yet to be cleaned up. (I like to use axles that are too long and cut them back afterwards as this suits my method of working with a (modified) George Watts quartering jig)

I have since had more success with some other stainless tube - same outside dimension but thinner walled and when this is used with the rod suplied by Eileen's provides more clearance and therefore less chance of material breaking through and shorting.

Today I have managed to assemble these and have them installed on a chassis for a Midland 1F (modified Craftsman) as shown below (please forgive the poor focusing on the photograph: I was anxious to get something posted quickly in response to the above). What (hopefully) the photo shows is the use of split axles and frames with CSB's (and the Gibson brass-centred wheels). I have built about six locos over the last two years to this spec (but this is the first with brass wheels) and oddly enough had not even given a thought to the alleged complexities of mixing CSB's with split frames. I'll try and get some better photos in due course. The red colouring on the wheels by the way is the remnants of some jewellers rouge I have been using to polish the treads. It works a treat but is a sod to clean off.

Here's the photo:

You may be able to see that I have filed the axle on the driven axle down to the boss and the smaller rod can just be seen surrounded by the light grey that is araldite/tube. The other axles have yet to be cleaned up. (I like to use axles that are too long and cut them back afterwards as this suits my method of working with a (modified) George Watts quartering jig)

You do not have the required permissions to view the files attached to this post.

-

billbedford

Re: Driving wheel axle material

hollybeau wrote:I am pleased to hear that you managed to get these materials to work together, Paul. Can I ask, when using the tube and rod from Eileen's, how you cut the tube after assembling it onto the rod?

It's best to cut the tube before assembling the axles. Also it is a good idea to make the inner rod slightly shorter than the axles, so if you have to trim the axle lengths your are only cutting the tube. You have to do this if you harden the rods, since there is no easy way of trimming them.

I have since had more success with some other stainless tube - same outside dimension but thinner walled and when this is used with the rod suplied by Eileen's provides more clearance and therefore less chance of material breaking through and shorting.

IIRC I used to us a 0.012in wall tube with a 1/16 in rod this gave enough room in the tube to put a twist of tread around the rod to prevent it sinking in the tube as the epoxy set, and shorting the two halves of the axle.

The red colouring on the wheels by the way is the remnants of some jewellers rouge I have been using to polish the treads. It works a treat but is a sod to clean off.

Just needs a quick dip in the ultrasonic.......

-

Paul Townsend

- Posts: 964

- Joined: Mon Sep 14, 2009 6:09 pm

Re: Driving wheel axle material

Useful responses to all who commented on my adventure into Splits and CSBs and methods of assembling tube axles deferred until later in the week.

Brain addled today by only 3 hours kip...ta to new intake students next door having a party last night...down side of large Victorian House close to University

Brain addled today by only 3 hours kip...ta to new intake students next door having a party last night...down side of large Victorian House close to University

-

hollybeau

- Posts: 91

- Joined: Thu Jul 30, 2009 10:03 am

Re: Driving wheel axle material

It's best to cut the tube before assembling the axles. Also it is a good idea to make the inner rod slightly shorter than the axles, so if you have to trim the axle lengths your are only cutting the tube. You have to do this if you harden the rods, since there is no easy way of trimming them.

Yes but..... doesn't that negate the whole point of making split axles this way? By having a "perfect" concentric tube and then cutting it once it is mounted on its rod (sorry, no smut intended) then the two halves will remain concentric. The moment that the tube is cut into halves and then assembled then however good the jig is that is used to hold it all together then innacuracies can occur. Doing it that way is no better/different than using solid parts cut with male and female halves a la Branchlines.

Look forward to your contribution Paul when you have caught up with some shut eye. I assume it is still Fresher's Week.

Bryan

-

David Thorpe

Re: Driving wheel axle material

I'm a bit confused. The way I've done it is to measure the tube and cut a bit off that's the length of the axle, trim it if necessary, cut a bit of rod to the length of the tube or slightly less, wind some thread round the rod, smear it with Araldite, ram it up the tube, test that the two are electrically isolated, then leave to set. Later, when the Araldite has set hard, cut all the way round through the outer tube (but NOT the inner rod!) where the insulation break is required. Provided that the rod and the tube are isolted from each other (which you've already ensured), this will leave the two halves of the tube also isolated from each other, with the inner rod ensuring that they remain perfectly concentric. Having assembled Bill's split axle kits in the past, I'm pretty sure that's what he meant too.

DT

DT

Return to “Chassis and Suspensions”

Who is online

Users browsing this forum: ClaudeBot and 1 guest