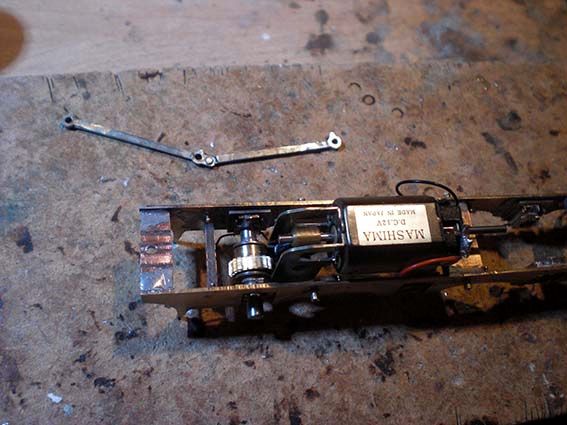

They were primarily for use in a small 0-4-0T tank/tram that I'm building and when ready I'll post its progress. In the meantime I thought I'd show how I've used some of the axles in a split axle chassis for a MR 0-6-0T. Sorry if this sends you to sleep.

[/URL]

[/URL]First I test the motor alone (not seen) then I test it with gearbox. The principle being that I only add one element of a build at a time and test. That way I know when the problems are creeping in. I built my first loco before testing ANYTHING. On the track it didn't move. I had no idea why. This approach is cautious, but seems to work.

[/URL]

[/URL]With the driven axle and gear in place. Very zzzzzzzzz, but that's me.

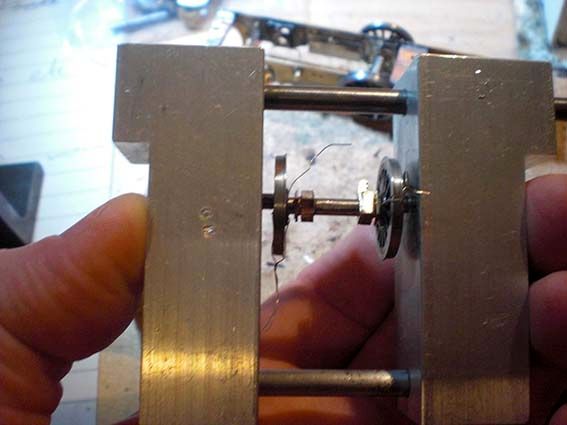

I like to treat the gears and washers with some fine wet and dry to ensure there are no burrs etc.

[/URL]

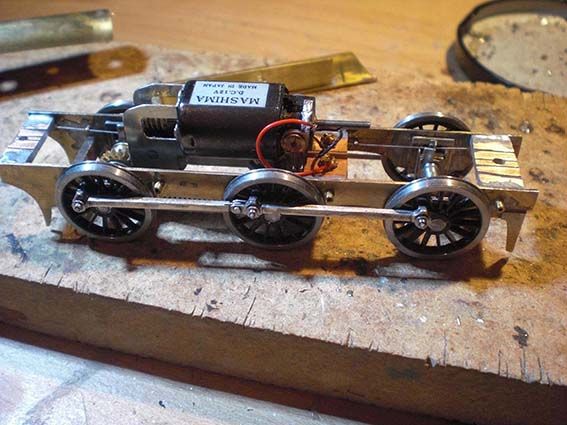

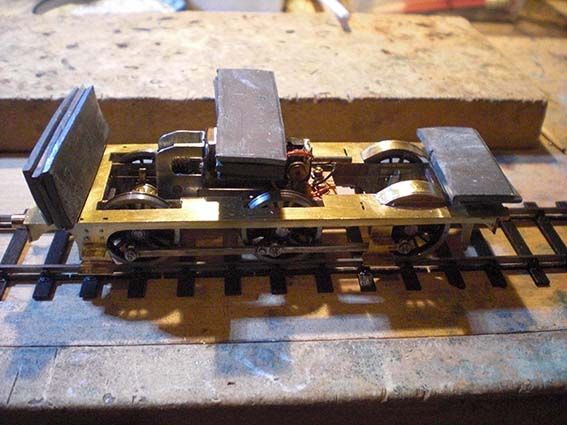

[/URL]Tested in chassis. This is my first CSB loco. So a few unknowns in the build for me. I've gratefully followed guidance from postings from Will; Russ and others .

High level gearboxes need high level testing.

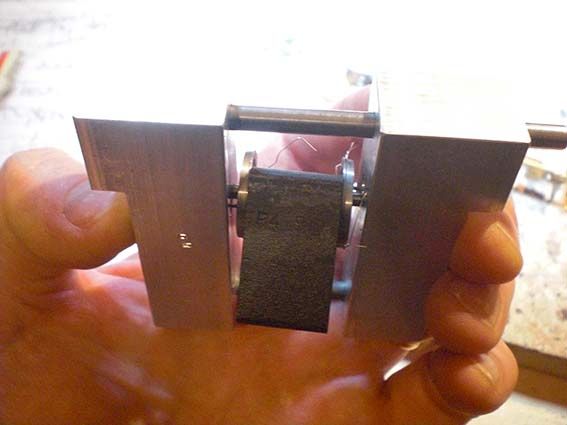

Out goes the guarantee on these Gibson wheels. I make a groove along the back of two spokes - opposite each other and NEVER anywhere near the crank pin. That can cause shorting problems (via the coupling rod. Believe me.) I also put a cut in the hub in line with the scored spokes to allow the shorting wire to bend along the axle.

Shorting the wheels. Note I don't solder the wires at this point. If you do that now, then when pressing the wheels on the wires are in tension and can break. Honest.

I love George's wheel press. Used with the b2b.

A low angle that shows wires are still not attached. Once pressed on they need guiding into the grooves cut in the spokes.

If you're ever going to find religion or become an alcoholic it's now. A very hot iron, flux and a quick dab is all that's needed. Honest.

The hornblocks are then slid into the chassis. Look! No pick ups! Horrid things. It's tested without and then with the coupling rods.These rods needed opening out a tad to get good running. The chassis must work at this point, or there's no point going on. I don't mean with life - just get the chassis running.

Hi-tech insulation is used (masking tape).

And checked.

Weights test. Whether you're building split frames or not, this is where the advantage of building the chassis BEFORE the upper body become obvious. This way it's easier to spot shorts and fouling points.

The boiler checked for clearance.

Almost a loco.

And checking ride height. The front is too high because I'd slipped too thick a piece of scrap plasticard under the body to ensure nothing shorted.

O.k you can wake up now. I'll post the 0-4-0T build soon.

Andy