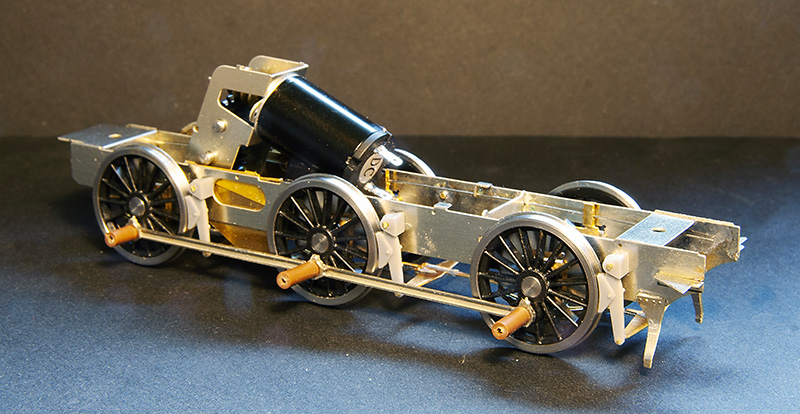

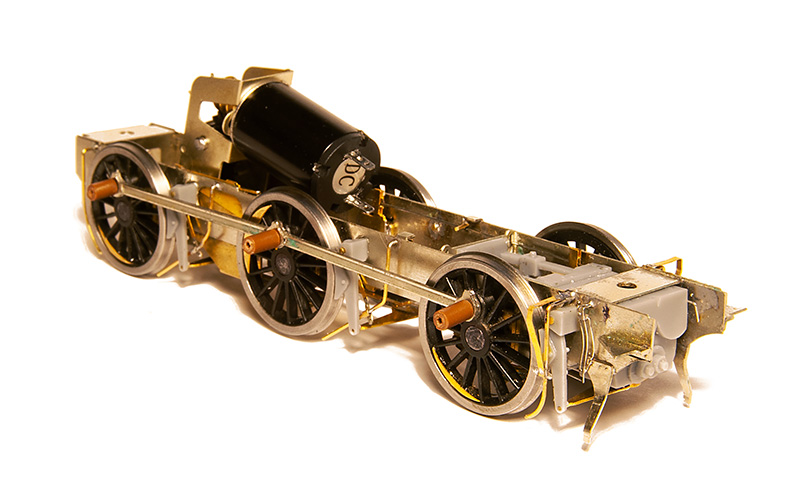

The basic chassis build with a High level Loadhauler gearbox. The loco and tender use CSBs throughout. The kit will be supplied with both printed and etched brake shoes.

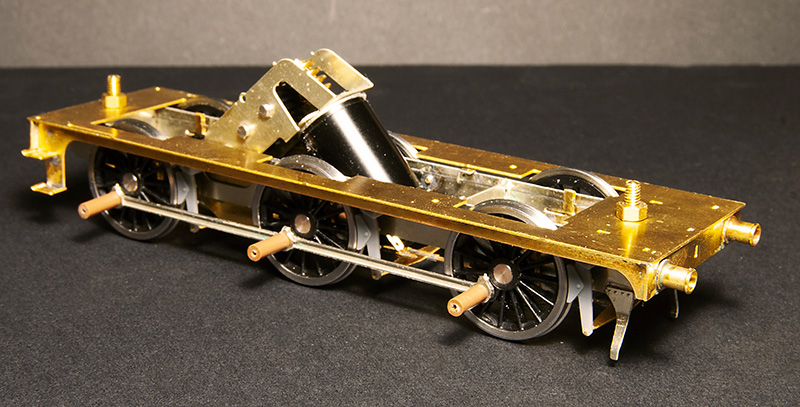

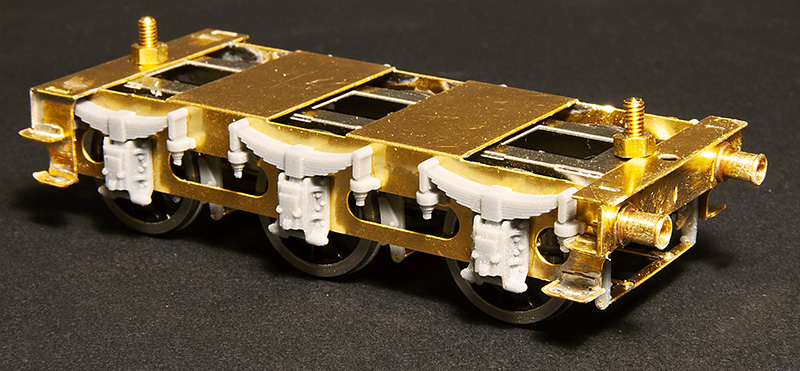

The tender subframe - Again with options on the brake shoes.

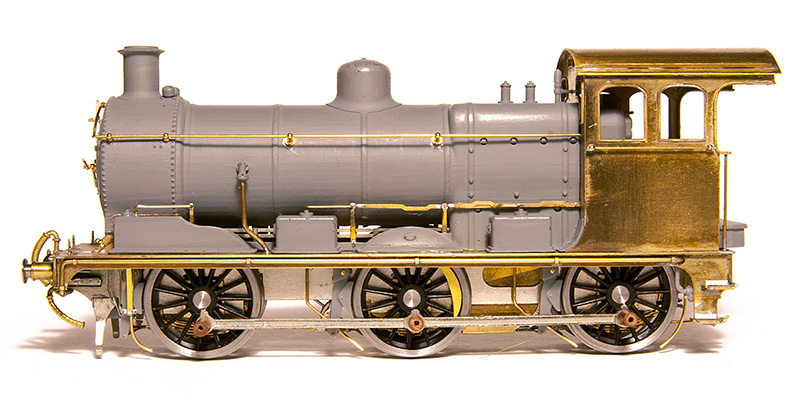

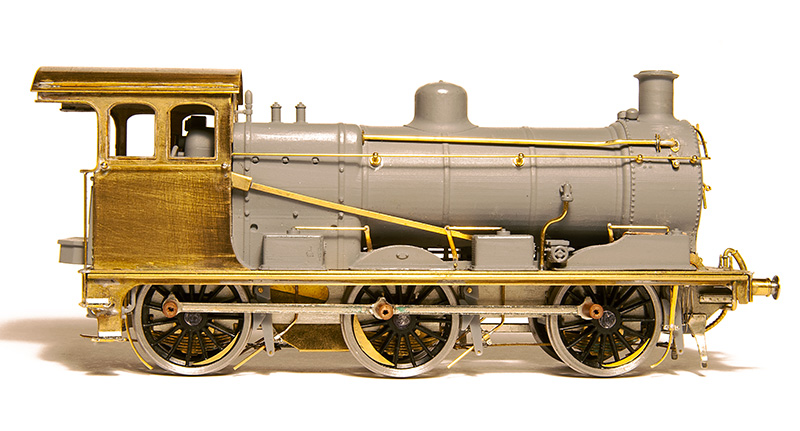

Chassis and footplate.

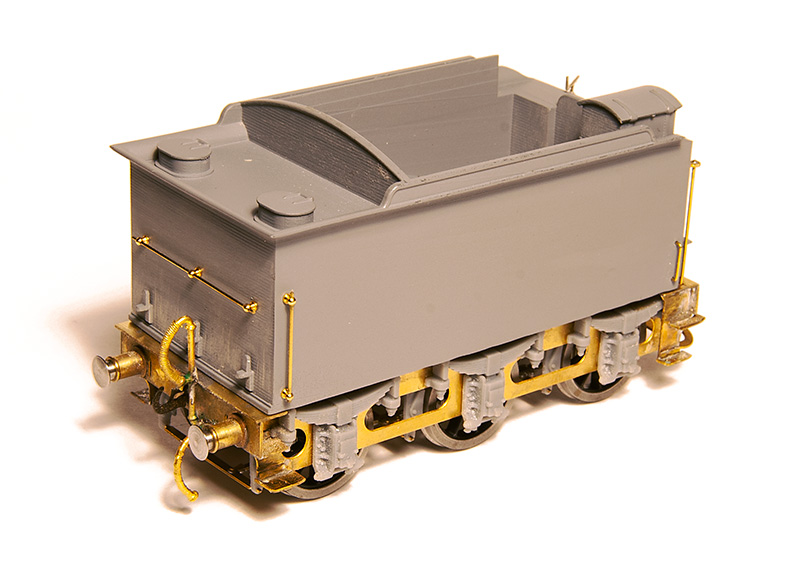

Tender with its outer frame.

The cab

Pretty much everything above the footplate and forward of the cab is catered for by a 3D print. Here I've made a start on the basic detailing

The tender body, like the loco, is a 3D print.

The detailed up chassis

The finished loco - More pictures below. This has been a pleasure to put together.